Manufacturing Services

MTSI Manufacturing Offers Turnkey & Consignment Assembly Services – Big or Small, We Do It All!

Expert Attention for Your Small Project Needs

- 3-D printing

- Box Build

- Functional and Parametric Testing

- SMT & Through Hole Assemblies

Material Procurement

We acquire essential raw materials and supplies for all projects and production.

MRP-II Computerized Operation

Using this computerized system optimizes manufacturing operations through integration of production planning, inventory management, and scheduling.

Access to In-House Stock of Parts

Our access to over 7 million in-house parts stock is crucial for lead time, to minimize downtime, and supporting production across industries.

Consigned Material Projects

We encourage consigned material projects where customers supply materials, reducing inventory costs and enhancing cost-effective production.

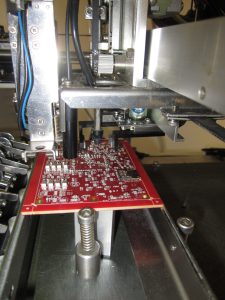

Circuit Board Assembly

SMT machinery populates and solders components onto boards to create functional electronic systems that meet world-wide ROHS standards

Leaded and Lead-Free RoHS Compliant Systems

We offer RoHS-compliant systems with leaded or lead-free solder options to meet environmental regulations in electronics manufacturing.

More Services

- Mechanical Assembly

- Electrical Assembly

- Turn-Key or Consigned Inventory

- Parts Procurement Service

- Sub-System / System Integration & Test

- Assembly Documentation

- CAD Design Services – Electrical & Mechanical

- Circuit Board Layout & Design Services

- Functional Testing

- Technician Services, Repair & Troubleshooting

Manufacturing Questions

The different steps involved in electronic manufacturing include:

- Design: The first step is to design the electronic product. This includes creating a schematic diagram and a layout of the printed circuit board (PCB).

- Prototyping: Once the design is complete, a prototype of the product is created. This allows the designers to test the product and make any necessary changes.

- PCB manufacturing: The PCB is then manufactured. This involves etching the copper circuit traces onto the board and assembling the electronic components on the board.

- Testing: Once the PCB is assembled, it is tested to ensure that it is functioning properly.

- Enclosure: The final step is to assemble the electronic product into its enclosure. This may involve assembling multiple PCBs together, as well as adding other components such as switches, displays, and batteries.

There are two main types of electronic manufacturing:

- Contract manufacturing: Contract manufacturing companies manufacture electronic products for other companies. This is a common option for companies that do not have their own manufacturing facilities.

- In-house manufacturing: Some companies choose to manufacture their own electronic products in-house. This gives them more control over the manufacturing process and allows them to make changes to their products more quickly.

The use of technology to improve the efficiency, productivity, and quality of manufacturing processes. It encompasses a wide range of technologies. MTSI practices smart manufacturing.

- analysis

- design

- testing

- Smart manufacturing: Smart manufacturing is the use of technology to improve the efficiency, productivity, and quality of manufacturing processes. This includes the use of IoT devices, AI, and big data analytics.

- Additive manufacturing: Additive manufacturing, also known as 3D printing, is being used to produce increasingly complex electronic components. This is helping to reduce costs and speed up the time to market for new products.

- Sustainable manufacturing: Electronic manufacturers are increasingly focused on sustainable manufacturing practices, such as reducing waste and using recycled materials.

The PCB is designed using a computer-aided design (CAD) program. The designer creates a schematic diagram of the circuit, which shows the electrical components and their connections. The designer then converts the schematic diagram into a layout, which shows the physical placement of the components on the PCB board.

Testing a PCB board is an important step in the manufacturing process. It ensures that the board meets all of the design specifications and is free of defects.