// Contract Assembles

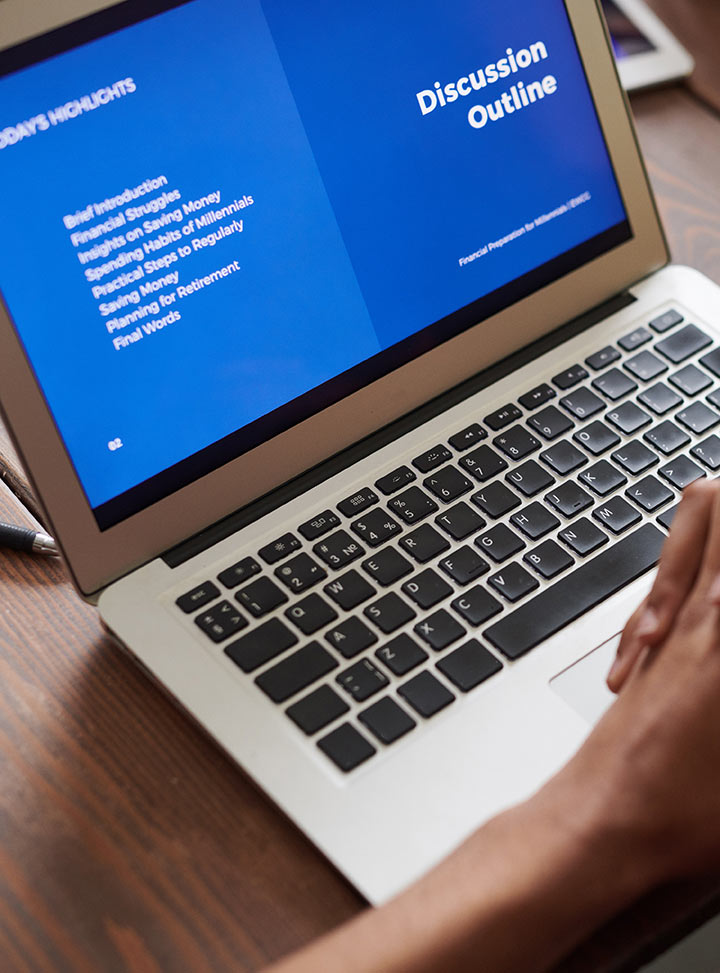

Manufacturing Services

MTSI Manufacturing Offers Turnkey & Consignment Assembly Services – Big or Small, We Do It All!

Expert Attention for Your Small Project Needs

- 3-D printing

- Box Build

- Functional and Parametric Testing

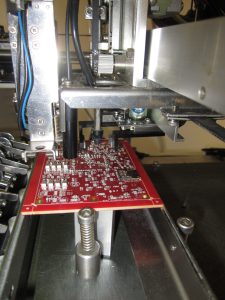

- SMT & Through Hole Assemblies