MRP – Precision at every step

Material requirements planning at MTSI

At MTSI, we’re proud to deliver contract engineering and manufacturing services for the next generation of products. Material requirements planning (MRP) assists our production processes by ensuring that the right materials are available in the right place at the right time.

From inventory management to confirm there are enough components in stock to meet demand, to creating detailed production schedules, and producing detailed records at every step of the manufacturing process, MRP helps reduce lead times and generate accurate demand forecasts – a valuable tool to cut down on waste and optimize resources.

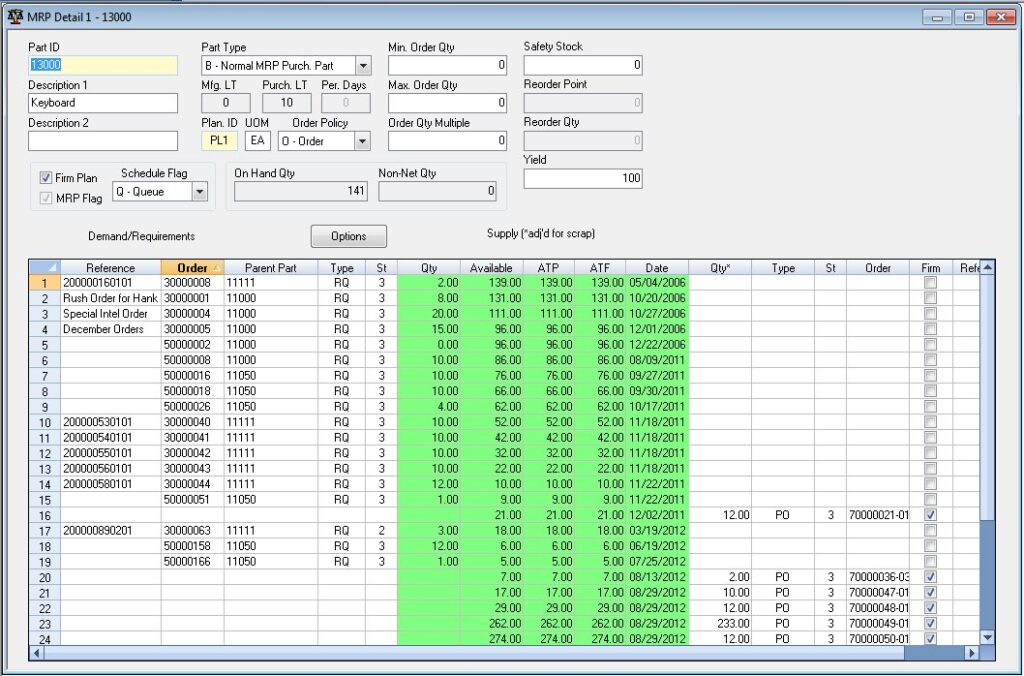

MTSI uses MAX ERP by ECI Software Solutions.

“Since we first installed the system – we’ve been doing it for 24 years – we cut our lead times from an average of 12 weeks down to five weeks,” MTSI founder Fred Beckhusen said. “We saved the entire price of the entire system in the first year alone – around $75,000 – in direct material savings by finding parts that were purchased that were no demand for from our old accounting mechanisms. It literally paid for itself the first year.”

Improved quality

At its core, MTSI uses MRP to produce documentation, which development teams track and approve. The system records all hours, and as a cost-accounting system, compiles the data so we know exactly what our costs are … at each step of the process.

For example, MTSI may buy a $20 part for a distributor, and we discover an additional 25% tariff – an increasingly common factor for many businesses. MRP allows us to handle the tariff or other costs up to the last minute, properly include them in accounting, and average them out in our system.

“The key thing about MRP is that it greatly lowers the lead time,” Beckhusen said. “I can tell one person by email that I need to order a component, and within a few minutes she has added it to a shop floor schedule, a purchasing agent will receive a notice, and she will find the best part at the best price, and issue the purchase order.”

“It’s all done electronically, there’s no paper really involved in this process. When you’re dealing with a part that costs $5,000, and it has 4,000 microscopic balls on the back that have been soldered perfectly, they require strict procedures.”

All that is to say, flexibility is crucial in circuit board design, where precise specifications may change frequently.

MTSI’s engineering change order (ECO) and engineering change notice (ECN) systems enable teams to quickly adapt to fluctuations in demand, production schedules, and design modifications. At times, engineers need to change a value or modification procedure. They produce a notice, and can change the revision – which we call revs for short – to keep track of the original rev and later rev.

There are also temporary revs. If the system records a rev “A” and an engineer needs to change the document, the change becomes “A1” in the documentation. Mark the change as rev “B,” that can be a signal to modify a physical circuit board, fab, filmwork – to image a double-sided board – or the screen for the solder mask, the thin layer of polymer which protects the copper during operation.

An engineer may need to change a procedure step. But as the changes ripple through the system, MRP tracks it all. If we ship something with rev “C” software with a rev “B” circuit board, that’s fine, because we have to use what the computer specifies. There’s no room for error.

Every step, every device

Recently, MTSI’s engineers closely studied a Raspberry Pi Compute Module 4 – a common microcontroller – to use in a project. The module had four tiny metric washers, which the team concluded were not needed. Foregoing the washers also made a better surface for the board and saved several dollars per unit.

“You have to buy them, stock them, kit them – and it adds up,” Beckhusen said. “We can go into the system and say ‘not needed.’ That’s through MRP.

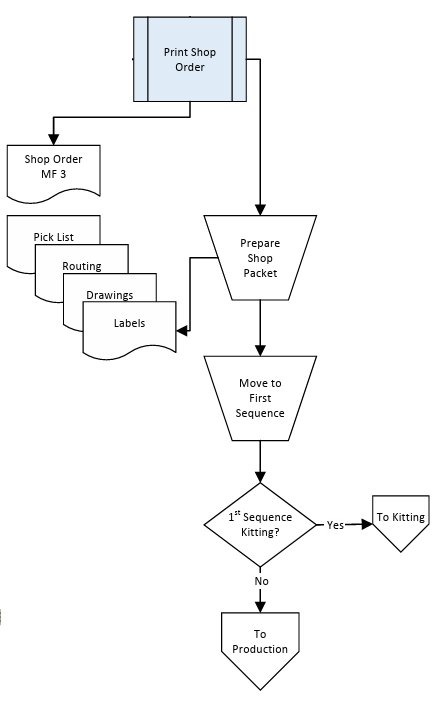

MRP also provides relevant and necessary documentation for future products in development. Teams can create different orders: planned, scheduled, or sales. MTSI may need to stock up parts well in advance. But a customer placing an order will create a sales order, which will generate a shop-floor order and its own specific documentation, which includes the quality control, hours taken, and each step including the work station name.

"We try to build a high-quality product. That’s how we get away with doing stuff for Airbus, NASA’s Jet Propulsion Laboratory and others, even though we’re a tiny company.”

Fred Beckhusen, CEO

That station may be touchup, surface mount technology (SMT), through-hole, or lead cutting – or to re-plate the back of the board. Some assemblies can’t have bare copper, which requires running the board back through the machine process.

The same is true for keeping everything in good working condition. Our automated optical inspection machine generates its own paperwork which shows us the yield rate – essential data for usable PCBs – which we run back through our statistics to see if something may be failing in the machine. Perhaps the machine begins drifting and is not placing parts right. This process will detect it before the machine breaks and production stops.

Additionally, PCB manufacturing needs clean air to blow over the boards, and clean water to wash them. It’s especially important to follow hazardous substances procedures to make sure there is less than a certain tiny percentage of lead used anywhere in the process, and to track every step on material hazard safety data sheets – and record everything in the computer.

Presently, MTSI employs three full-time quality assurance professionals who are certified for software, procedures, and full visual inspection of our boards. In all, “we try to build a high-quality product,” Beckhusen said. “That’s how we get away with doing stuff for Airbus, NASA’s Jet Propulsion Laboratory and others, even though we’re a tiny company.”

As for MRP, it took MTSI around six months to first transfer its data into the new system, but “we were productive literally the first day, and it paid for more than the whole system,” Beckhusen added. Those savings started immediately as the system tracked down unneeded parts in the inventory. “It’s nice. Still is.”