Contract Manufacturing Services

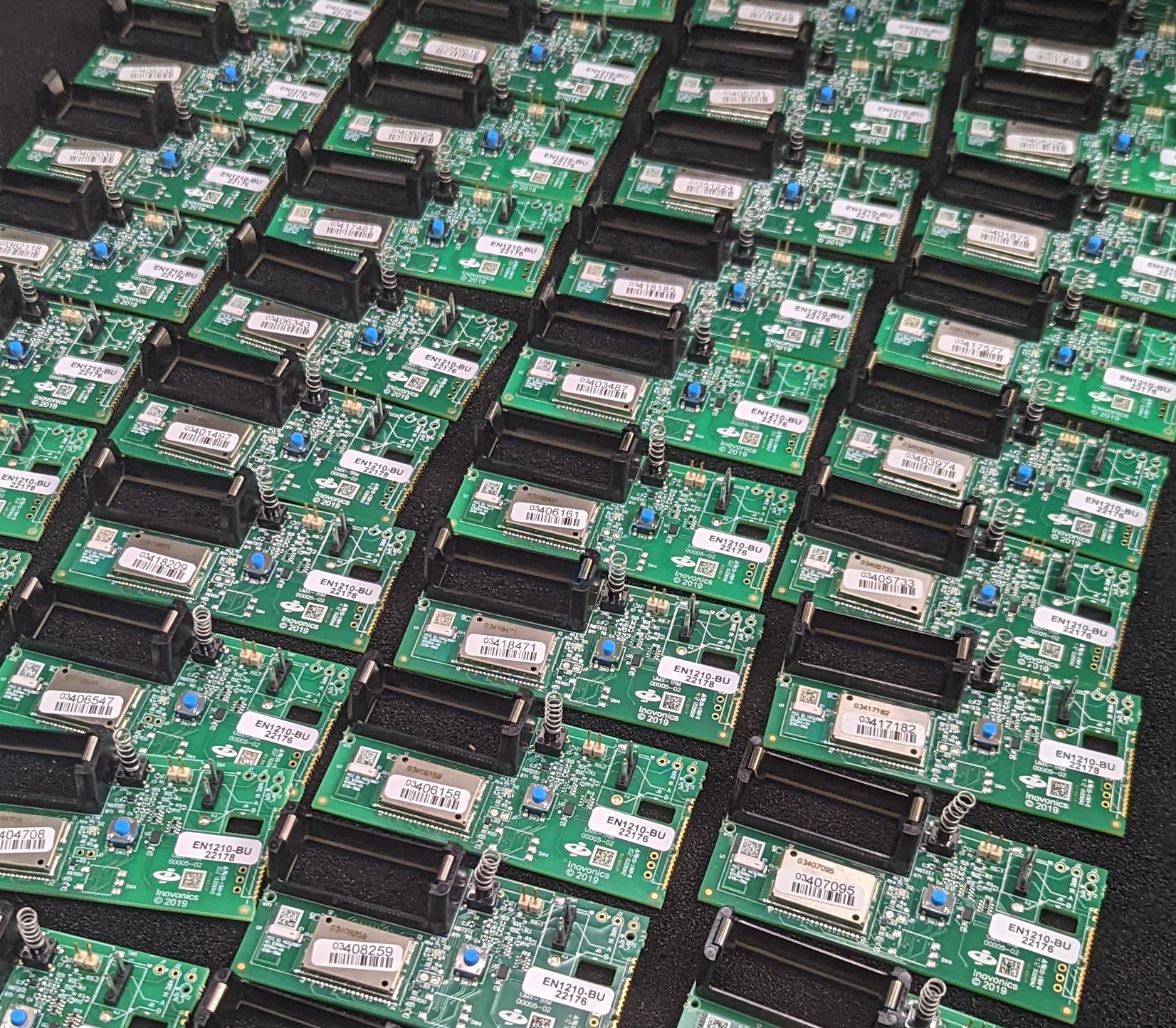

We offer a range of electronic contract manufacturing services from PCB assembly, turn-key solutions, circuit board layout and design, and system integration and functional testing.

MTSI offers a wide variety of electronic devices – from simple circuits to complex printed circuit boards; from prototypes to production. For more than 30 years, we have supplied customers with surface mount technology (SMT) to deliver high-quality, reliable SMT components that meet or exceed the diverse needs of our clients across industries.

Located in the U.S.A.

U.S.-sourced manufacturing services for your small project needs.

Surface mount technology: Smaller, faster, better contract manufacturing services.

SMT is an adaptable and robust process for manufacturers looking to produce devices with smaller footprints. MTSI helps our customers at every step of the process from prototyping to testing every component.

Read on for details or contact us to get in touch.

The miniaturization capabilities of SMT technology enable the creation of smaller, lighter, and more portable electronic devices.

LEARN MORESMT

RoHS reduces the use of hazardous materials in electronics, which in turn reduces the environmental impact when these products are eventually disposed of or recycled.

LEARN MORE

Our automated optical inspection includes precision to meet high-quality standards, ensures that our products meet strict quality criteria.

LEARN MOREQuality Control

How does SMT work?

Surface Mount Technology (SMT) is a method used in electronic assembly to mount electronic components directly onto the surface of a printed circuit board (PCB). This stands in contrast to traditional through-hole technology, where components have leads that pass through holes in the PCB and are soldered on the other side. SMT offers several advantages, including smaller PCB size, higher component density, and improved manufacturing automation.

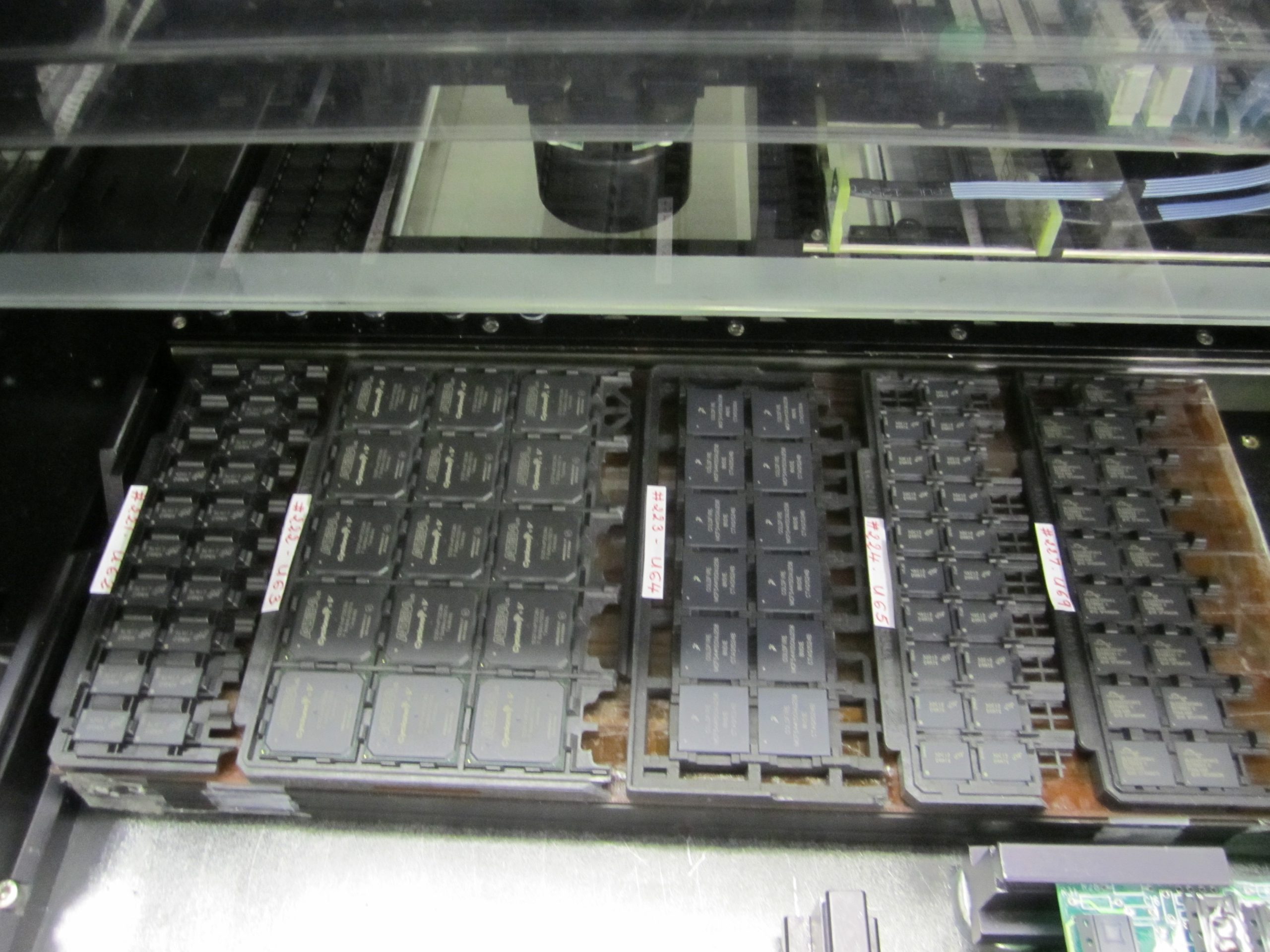

In SMT, electronic components are typically small and lightweight, with no leads or with very short leads called surface mount devices (SMDs). These components are placed on the surface of the PCB using automated pick-and-place machines. The PCB itself is coated with solder paste, a sticky mixture of tiny solder particles and flux. The solder paste is applied to the PCB through a stencil, leaving deposits on the pads where components will be placed.

After the components are accurately placed on the solder paste, the entire assembly is subjected to a reflow soldering process. This process involves heating the PCB to a temperature where the solder paste melts and creates a connection between the component leads and the PCB pads. The molten solder then solidifies, creating a reliable and durable solder joint. Modern SMT processes use infrared or convection reflow ovens for precise temperature control during soldering.

Once the soldering is complete, the PCB undergoes inspection to ensure the quality of the solder joints and the correct placement of components. Automated optical inspection (AOI) and X-ray inspection are commonly used to detect any defects or issues.

- Component Miniaturization

- High Component Density

- Improved Performance

- High-Speed Electronics