Shellback Joins TEL's Mission to Produce the Cleanest Wafers

MTSI's part in high-volume semiconductor manufacturing

For many years, MTSI has been proud to design and manufacture printed circuit boards (PCBs) which power the equipment used in wafer processing for clients such as FSI International, which merged with Tokyo Electron Ltd. (TEL) in 2012, and sold some of that high-end technology to Shellback. In November 2023, Shellback Semiconductor — a leader in semiconductor capital equipment and services — acquired the Mercury™+ batch spray cleaning product line, a washing system for 100 to 200mm wafers, from Tokyo Electron.

Wafer cleaning is one of the top engineering challenges in semiconductor manufacturing, requiring more complex and fine-tuned machines carrying out hundreds of steps.

Leveraging expertise and precision at any step of development, MTSI continues to provide the smart, flexible approach to building those machines — while lowering costs, ensuring long-term reliability, and on-time production of the technologies that turn matter into thinking machines.

Demand for U.S. semiconductor design and manufacturing is growing, and expected to reach a trillion-dollar industry by 2030.

MTSI is committed to helping clients build these systems — and keep them running — for years to come.

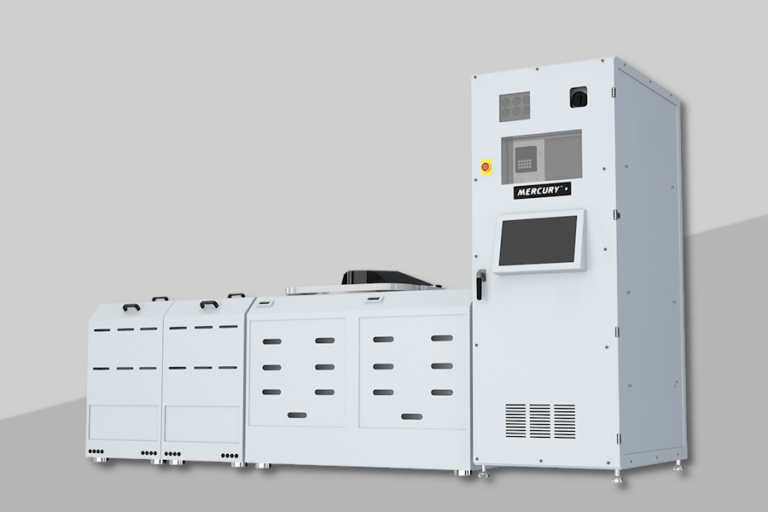

COOPERSBURG, Pa., Nov. 9, 2023 /PRNewswire/ — SHELLBACK Semiconductor Technology, an industry leader in batch spray equipment solutions, announced today the acquisition of the MERCURY™+ batch spray cleaning product line from Tokyo Electron Limited (TEL™). This acquisition, which includes MERCURY™ and MERCURY™+ products, makes SHELLBACK’s batch spray product portfolio the most comprehensive in the industry.

SHELLBACK’s agreement with TEL includes intellectual property rights for the MERCURY™+ product line granting SHELLBACK the ability to provide new & remanufactured systems, upgrades, parts, and field service support to the industry worldwide. This includes the upgrade of existing systems at customer fabs with the new MERCURY™+ controller. SHELLBACK plans to utilize their newly enhanced corporate headquarters and manufacturing center in Coopersburg, PA to design and manufacture new MERCURY™+ systems and upgrades, and to provide parts as well as technical support.

Wayne Jeveli, CEO of SHELLBACK said, “MERCURY™+ is a great complement to our existing industry leading wet process technology, with high throughput capabilities that make it ideal for emerging markets like Power Devices and MEMS. We thank Tokyo Electron for selecting SHELLBACK for this acquisition, and we look forward to working with their global team in the coming months as we transition the responsibilities for this product line. Our mutual priority is seamless support for our customers.”

Mark Dougherty, Tokyo Electron America & TEL Manufacturing and Engineering of America President said, “The MERCURY™+ product line transition to SHELLBACK aligns perfectly with our intended market focus and ensures that our shared customers have continued access to the spectrum of products that best fit their technology and production needs. Tokyo Electron will now focus our innovative energy on further enhancing the broad, advanced capabilities of the Zeta™+ 200mm and 300mm family of spray batch cleaning technology to meet the future needs of our valued customers.”

More on MERCURY™+

MERCURY™ / MERCURY™+ is a best-selling batch spray cleaning system that answers customers’ high-variety, small-lot production needs. With only a simple hardware change, the same system can be used to process 200mm, 150mm, and 100mm wafer batches, making it ideal for new and emerging markets that require production flexibility in a reduced footprint.

About SHELLBACK

SHELLBACK Semiconductor Technology represents the union of two industry-leading proven semiconductor brands—OEM Group and RITE TRACK—with a combined 50-years of experience around the globe. Sharing a commitment to pioneering intellectual property and unparalleled customer service, SHELLBACK provides new and remanufactured semiconductor capital equipment and services to enable emerging and legacy markets, such as Power Devices, Photonics & LED, MEMS & Sensors, Wireless & Analog, and Memory/ Storage. With one of the industry’s largest installed bases of equipment at over 700+ customers world-wide, SHELLBACK offers proprietary products from SEMITOOL, VARIAN, Applied P5000, SVG Track, and more, as well as a combination of best-in-class technologies for Wafer Carrier Inspection and Cleaning—the EAGLEi and STORM.

About Tokyo Electron Limited

As a leading global company of semiconductor production equipment, Tokyo Electron Limited (TEL) engages in development, manufacturing, and sales in a wide range of product fields. All of TEL’s semiconductor production equipment product lines maintain high market shares in their respective global segments. TEL provides outstanding products and services to customers through a global network of approximately 83 locations in 18 countries in the U.S., Europe, and Asia.

For media inquiries reach out to Tom Parish at [email protected]