Giving Torpedoes the Edge With Digital Signal Processors

Hardware for tomorrow’s U.S. Navy delivered today

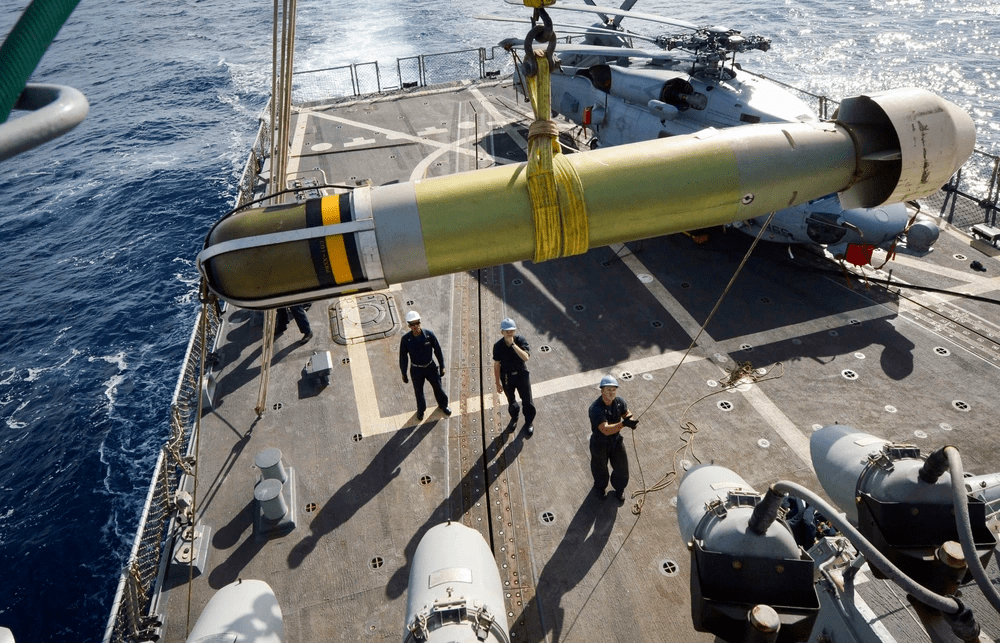

The U.S. Navy’s submarine fleet is always working to remain several steps ahead. MTSI redesigned and manufactured an important piece of the Mark 54 Lightweight Torpedo using digital signal processors. The result is a more capable Navy, equipped to meet the adversary.

The Mark 54, formerly known as the Lightweight Hybrid Torpedo, entered Navy service in 2004 as a more affordable and capable means to operate against relatively slow conventional submarines in littoral waters. The proliferation of these smaller but capable diesel-electric submarines by near-peer adversaries pose challenges for the U.S. Navy and reflect the changing dynamics of undersea warfare.

Dealing with that challenge is complicated in an underwater environment. The depths might sound eerily quiet to human ears, but the sea is incredibly noisy, and sound travels a long way.

Electronic systems not only have to discriminate and filter what they hear but work in real time — if they fall behind, the signal gets distorted. If it is too slow, then it will miss something important.

Digital signal processors (DSP) convert analog input into digital form and processes it with mathematical algorithms to improve quality.

That has many computational benefits and enabling greater effect in filtering, integrating, and controlling competing signals and noise — like a recording studio filtering out the mechanical imperfections to get the pure sound of a symphony.

DSP also has an advantage over microprocessors, which can be more versatile, but without the speed and dedication to a specific or group of tasks.

The benefits are obvious for a wide variety of defense applications. In a torpedo, digital signal processors allow for real-time processing of sensor data for guidance and control systems, such as sonar signals, to detect and track targets underwater — enhancing the torpedo’s ability to discriminate between different objects and then pursue and engage the intended target.

"There are innumerable examples of the use of DSPs in military systems. Broadly, these uses include airborne Doppler radar and moving target indicators; target recognition using signature analysis of radar reflections; and both active and passive sonar signature analysis. With sonar networks, the real-world inputs from arrays of hundreds of hydrophones monitoring vast underwater domains would literally swamp processors with less agile computational throughputs. In addition, DSP uses extend to telecommunications, speech processing and synthesis, acoustic homing weapons, satellite and terrestrial imagery and a host of other 'high technology' operations."

The Journal of Electronic Defense

Moreover, to enhance communication between the torpedo and its launch platform, DSP assists in the encoding, decoding, and filtering of communication signals, enabling secure and reliable data exchange. Integrating off-the-shelf boards also allows military systems to be developed faster and at a lower cost. This benefits the systems integrator, the end user and, in the case of military systems, the taxpayer.

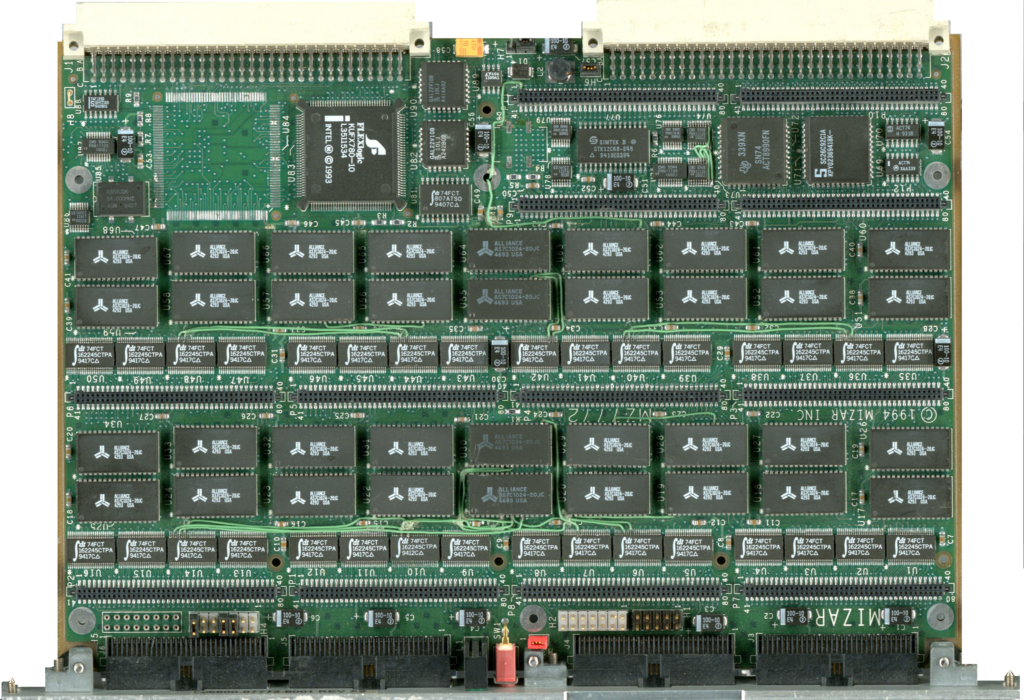

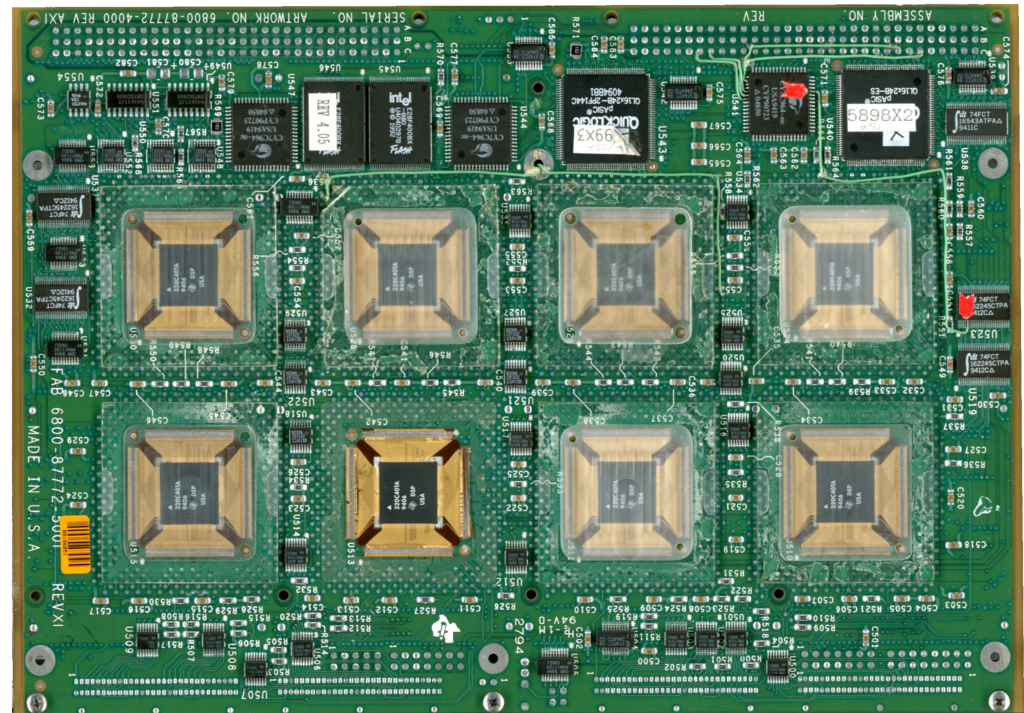

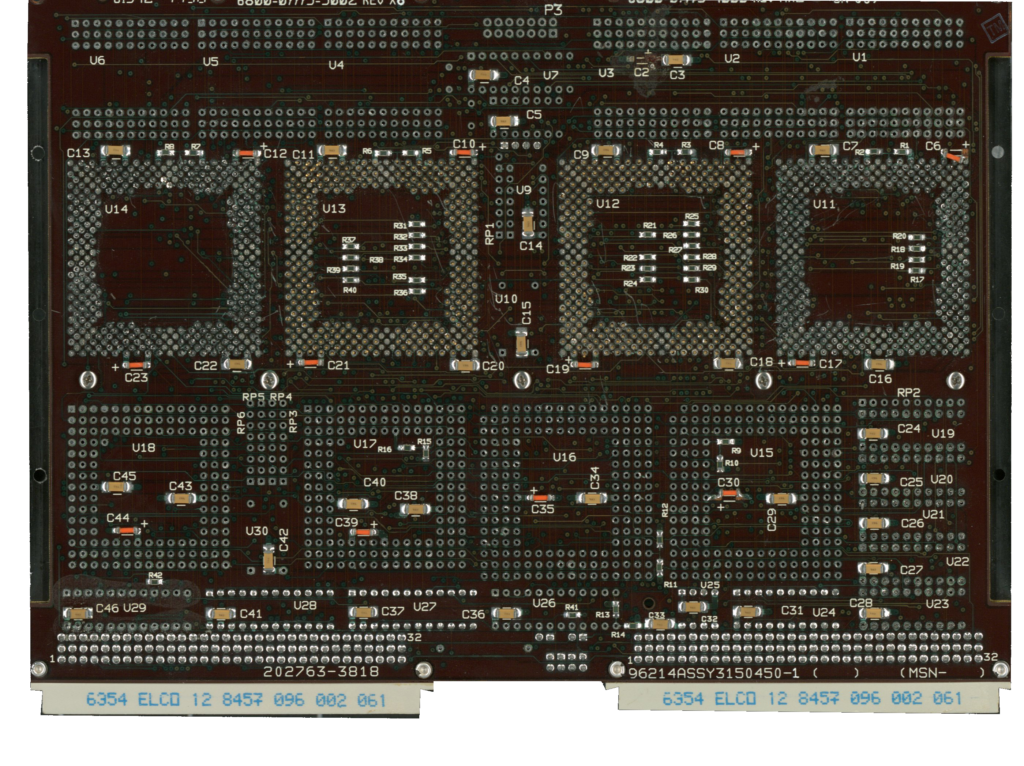

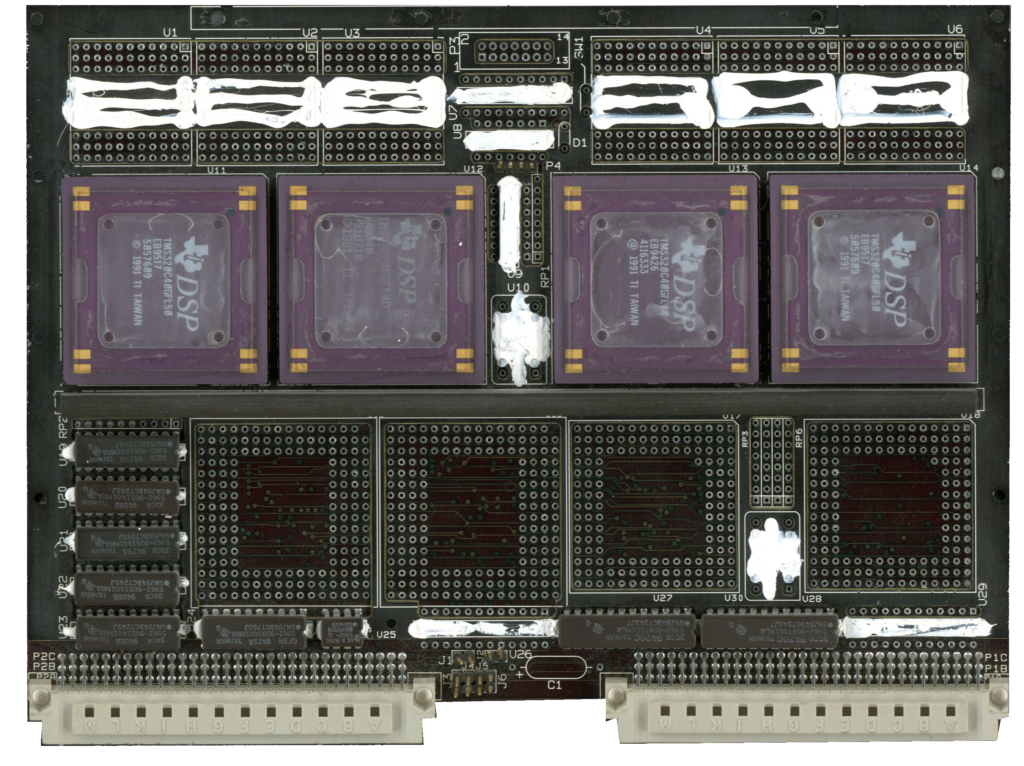

The cards pictured here are the octal Tape-Automated-Bonding commercial version and the metal core, 400 G Mil-rated octal version.

Solution

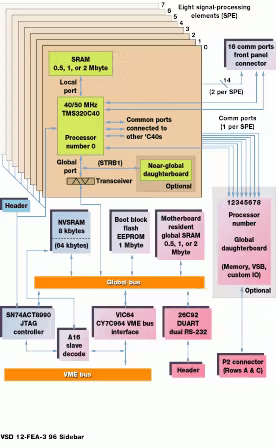

MTSI redesigned the Mizar/Motorola M772-8 octal VMEBus card and replaced the FPGAs. These applications used Mizar’s Octal “C40” boards based upon the commercial Texas Instruments TMS320C40 programmable floating-point DSP. The multiprocessor design included six parallel communication ports, independent DMA, which marked an improvement over earlier designs and was effective as an interprocessor for communications channels in multiple processor architectures.

The 7772 went further as it was capable of a direct link to as many as eight megabytes of zero-wait-state SRAM.

The single-board computers were ruggedized for installation in torpedoes and capable of withstanding significant structural shock loads up to 400 g.

The card featured one, two, four or eight T.I. TMS320C40 DSP at 40 megaflops, and 2.2 giga integer operations per second. It used state-of-the-art tape automated bonding (TAB) packaging technology which increased chip density and reduced manufacturing costs.

The front panel IO could handle 320 MB/second I/O, with 2.56 gigabytes per second concurrent data transfer rate between DSPs, and JTAG debugging. A set of five boards were linked together in the VME Bus chassis to process sonar readings. The overall throughput was 200 megaflops per second with 11 billion integer ops per Second (IOPS).

Mizar supplied the SBCs to Hughes Aircraft Corporation, Weapons Systems Segment, Naval and Maritime Systems. Hughes, in turn, was a subcontractor to Alliant Techsystems which served as the prime contractor on this program. Raytheon later acquired Hughes. Additionally, Mizar’s DSP-based multiprocessor was utilized in the heavyweight torpedo program upgrade to the Mark 48 Advanced Capability (ADCAP) Common Torpedo-Development Vehicle (COT-DV).

MTSI is proud to harness the capabilities of digital signal processors which power deterrence and achieve capabilities at the edge for the U.S. and allies. The result is a more capable Navy- — a silent service equipped to meet the adversary.

Robert Beckhusen

Robert Beckhusen is a case studies and content marketing editor for Micro Technology Services.