Case Studies

These engineering projects range from the 1970s to today. See how a lock washer can cause a fire, or how innovative engineering can create a huge market for microwave ovens almost overnight.

Discover how Brunswick Bowling & Billiards developed Bowler Vision, computerized color bowling displays running alongside the real-life players going for the strike.

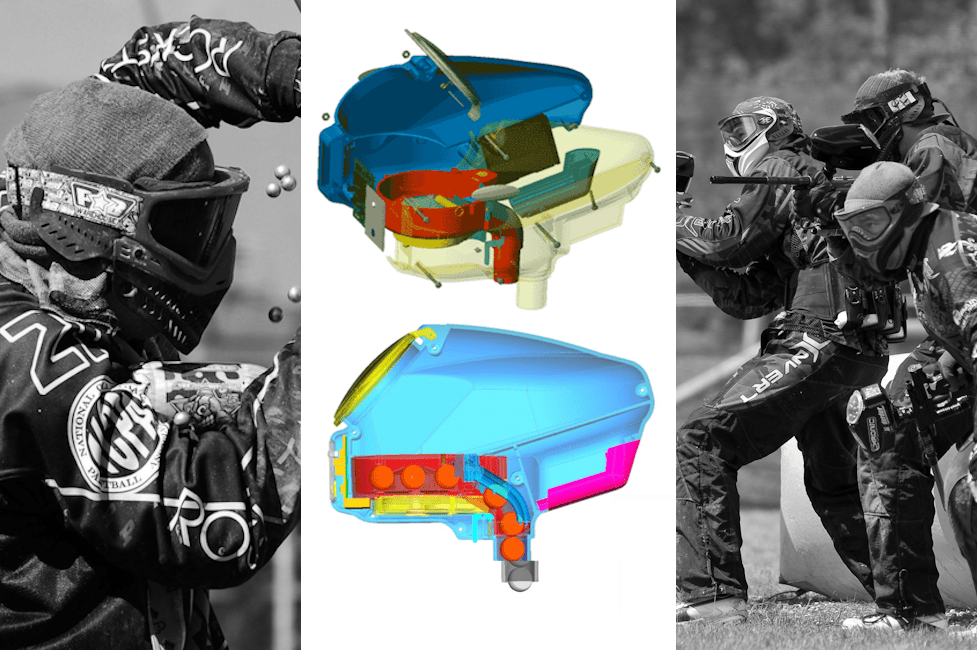

To win the paintball arms race, MTSI engineers came up with a classic example of great design — the Odyssey HALO paintball loader.

Litton (later acquired by Northrop Grumman) approached MTSI to help engineer the first truly digitally fused thermal/night vision camera.

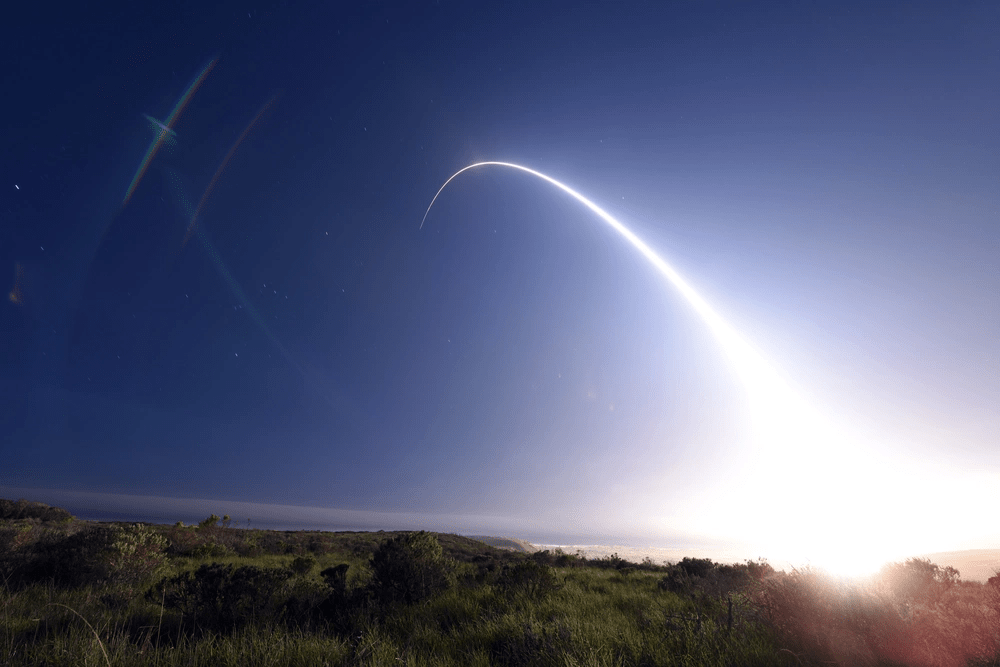

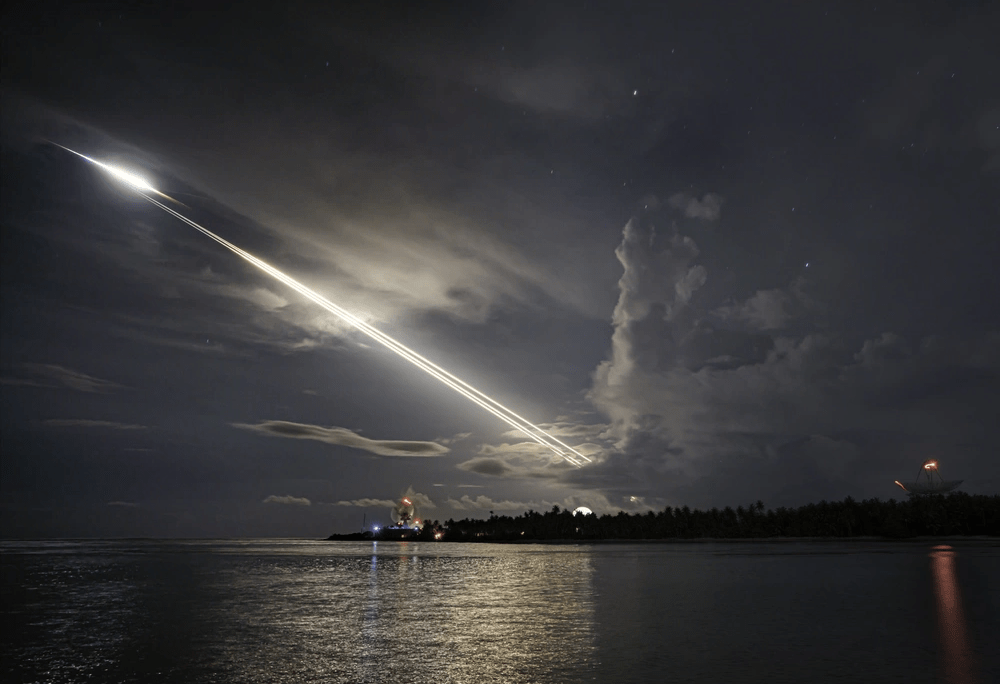

MTSI reverse engineered and replaced two testing systems which the Air Force successfully deployed in Minuteman missile programs.

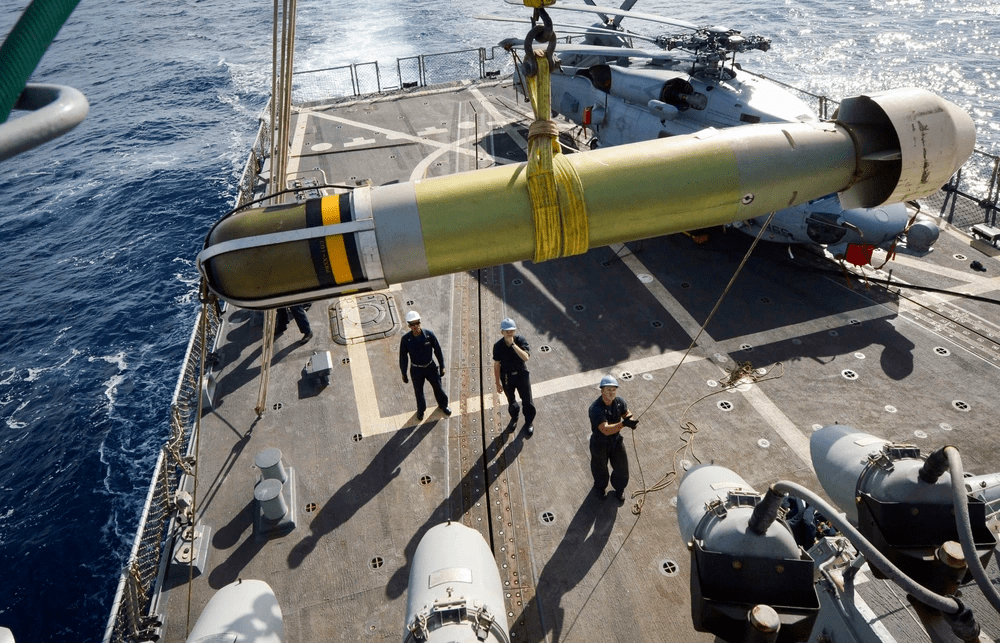

The U.S. Navy is always working to remain several steps ahead. MTSI redesigned and manufactured an important piece of the Mark 54 Lightweight Torpedo using digital signal processors.

Late one night in 1977, I discovered one of the world’s first computer viruses.

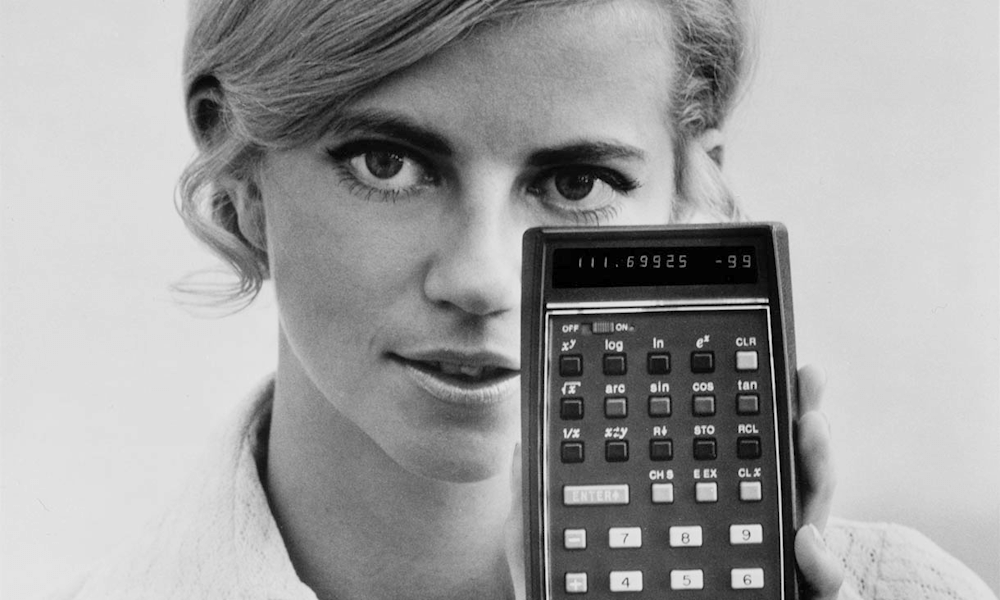

The HP-35 calculator was the first handheld, battery-powered scientific calculator. I was awestruck and had no idea that I would soon work on them at an intimate level at the very company that designed and made the HP-35 ICs.

Air forces need to maximize their training readiness. MTSI designed an all-digital, fly-by-wire gauge for the BAE Hawk’s tailplane, enhancing precision and responsiveness.

Medi+Beep a start-up company wanted to produce a electronic medication reminder that could remind you when to take your medicine and which medicine to take — and make a beep.

Dozens of these custom MTSI systems were used by the USAF to evaluate its missiles.

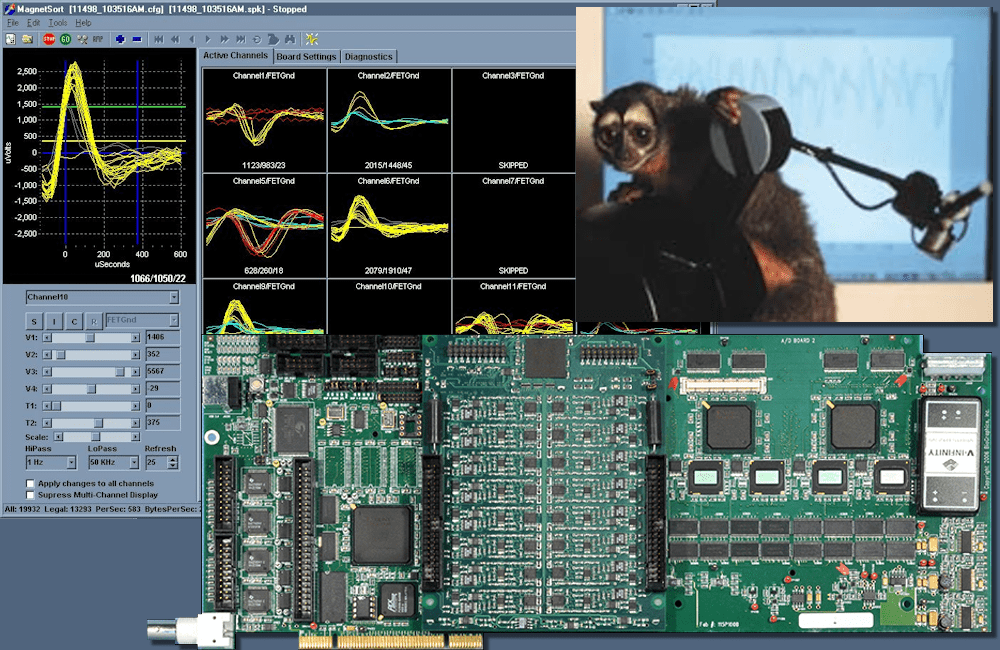

MTSI is proud to have played a part in an early breakthrough in brain-computer interfaces for controlling robots with the mind.

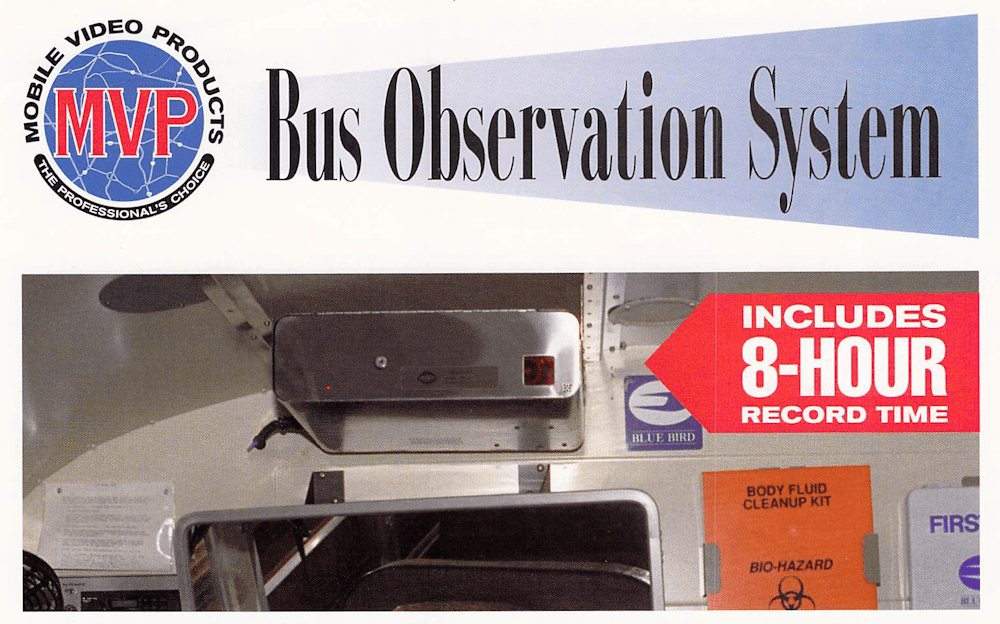

A small Texas company that repaired school bus seats patented a video recorder for school buses and came to us for help.

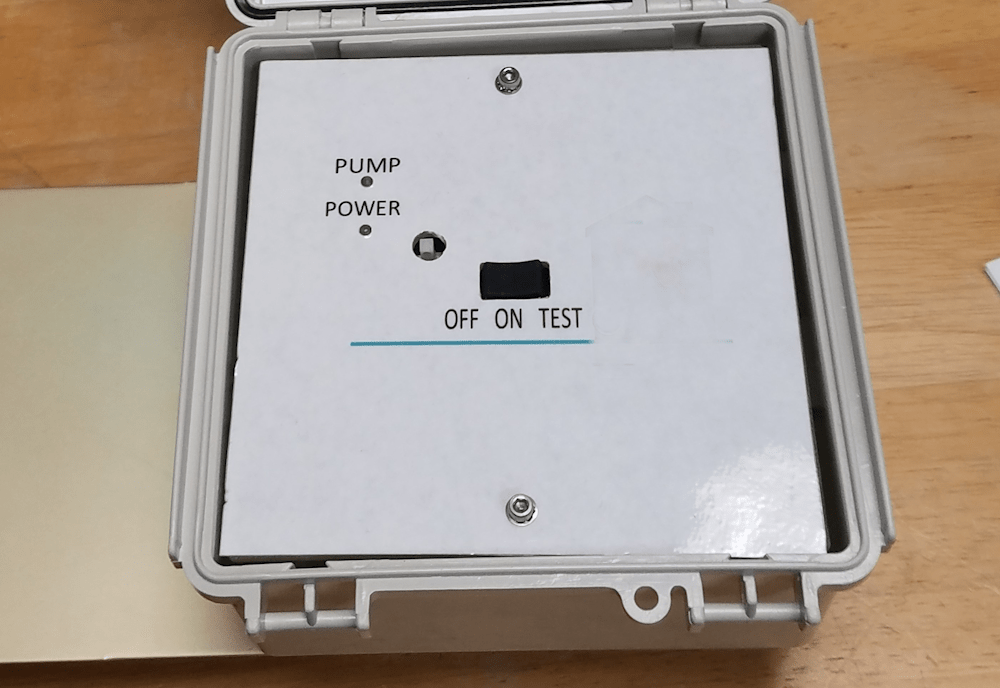

A client needed a watertight liquid pump controller that is set by a cellphone using Bluetooth. MTSI designed a dual CPU circuit with a Bluetooth chip and a controller using a small 8-bit microprocessor.

This magnetic two-way medical scanner controls an embedded implant in healing bones. The client wanted the device to sound like a ‘Star Trek’ scanner.

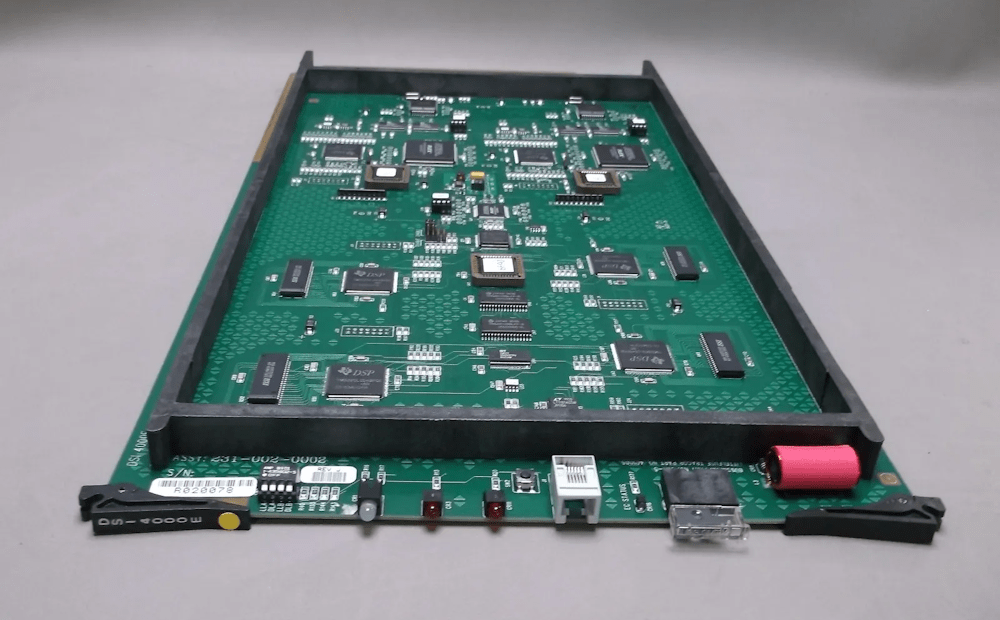

Telecom signaling requires echo cancellation and acoustic coupling control even on digital circuits. MTSI developed an algorithm that was capable of handling a T-1 line with an 88 percent reduction in DSPs with the digital trunk interface.

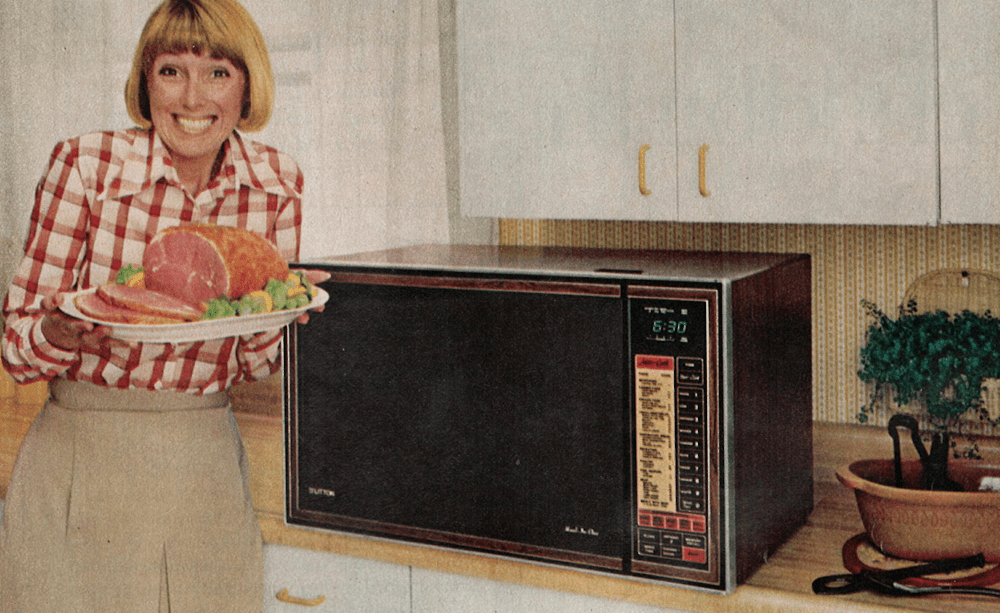

The Litton Auto-Cook microwave was the first oven on the market to take the guesswork out of cooking. MTSI made it easy by helping develop the machine.

Carhackers broke an almost unhackable chip set used in millions of vehicles. A client approached MTSI’s engineers to diagnose the exploit and invent a solution.

A Nortel senior vice president had a problem – he needed a new phone and he needed it in three months. It took one trip to MTSI to get the job done.

Lennox is a longstanding HVAC company and in 1982 introduced its classic Lennox Pulse furnace. These high-efficiency units are known for their distinctive “pulsating” sound. MTSI helped make the Lennox Pulse heater possible.

MTSI has worked on Coke machines, Pepsi machines and others for major vending machine companies. This refrigerator controller for Schooner’s Bay was designed to control the temperature of the drink to within 0.2 degrees C of 32 degrees F (0 C).

This logic board automatic tester was designed to test the computerized coin changer modules used in vending machines.

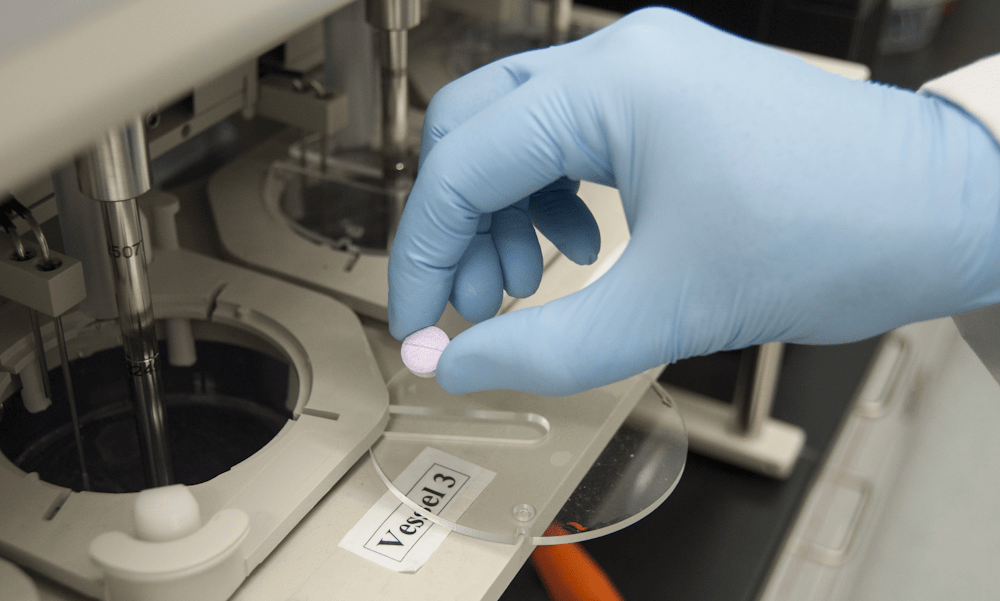

Our client envisioned a microcomputer-controlled, precision, intravenous infusion pump for hospital use. This device could play a crucial role in healthcare settings.

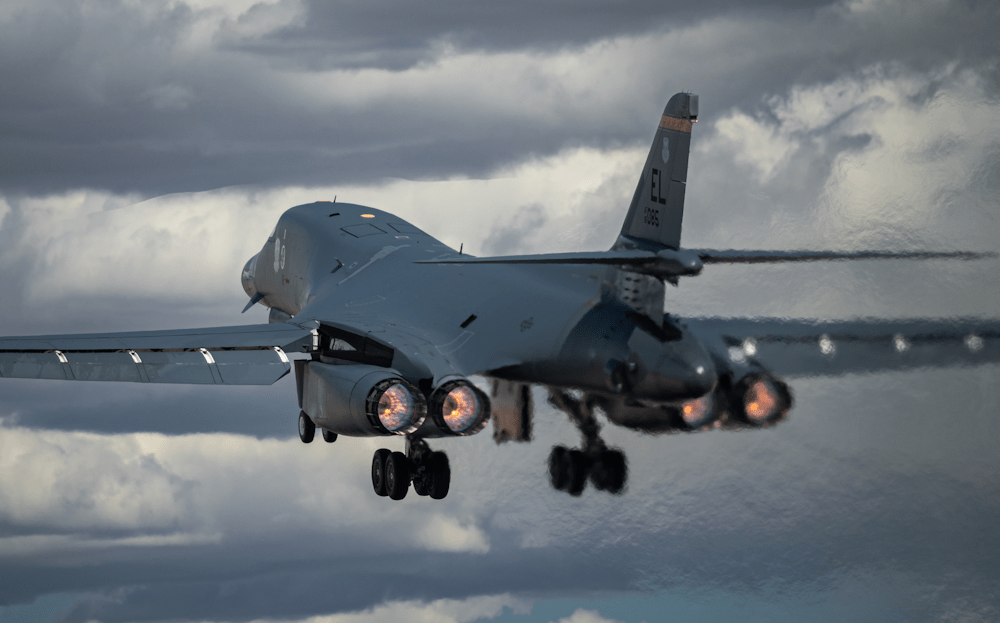

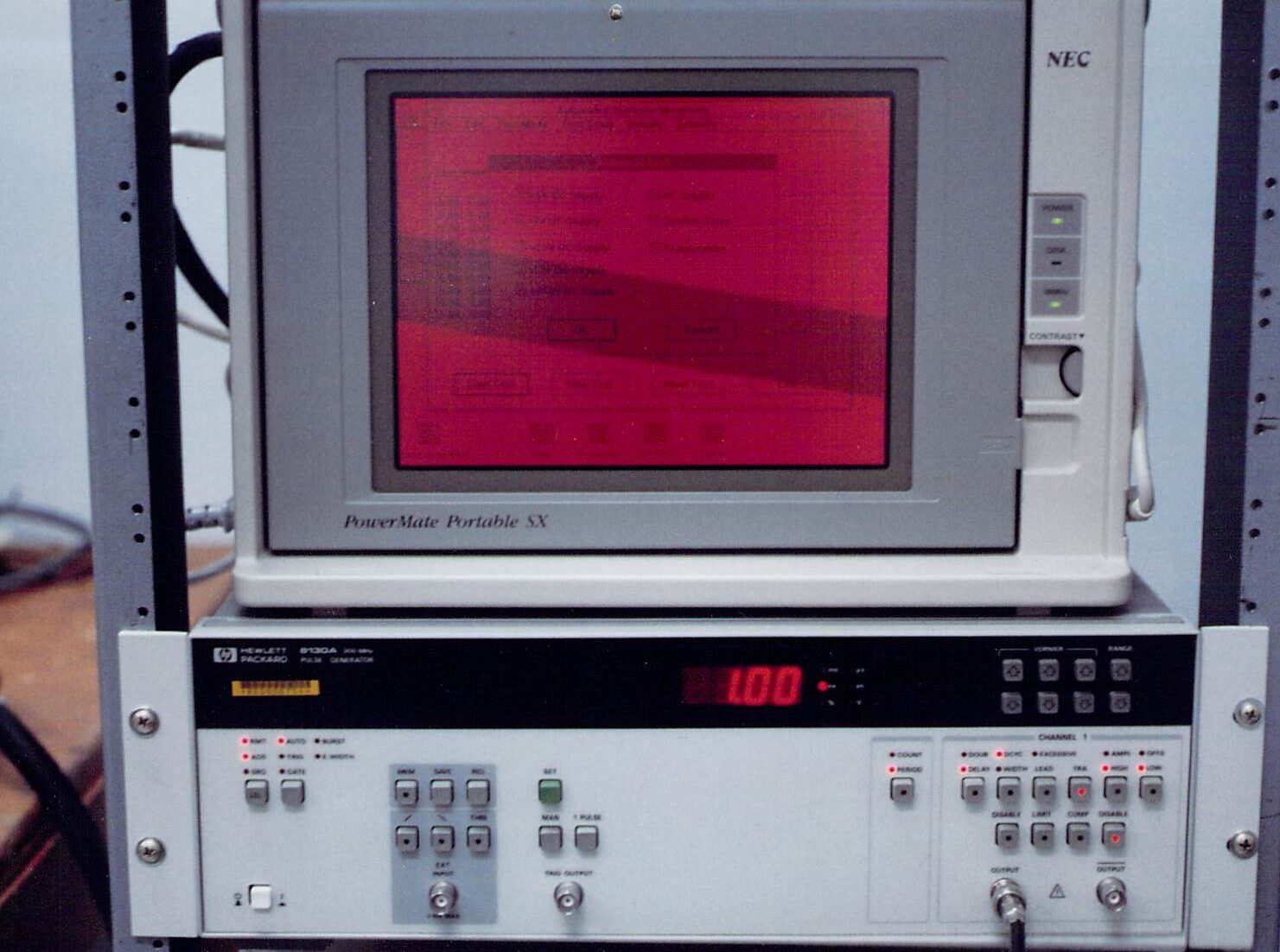

A major defense contractor had a problem with their ATLAS software and hardware systems used in U.S. Air Force systems. They approached MTSI for a solution.

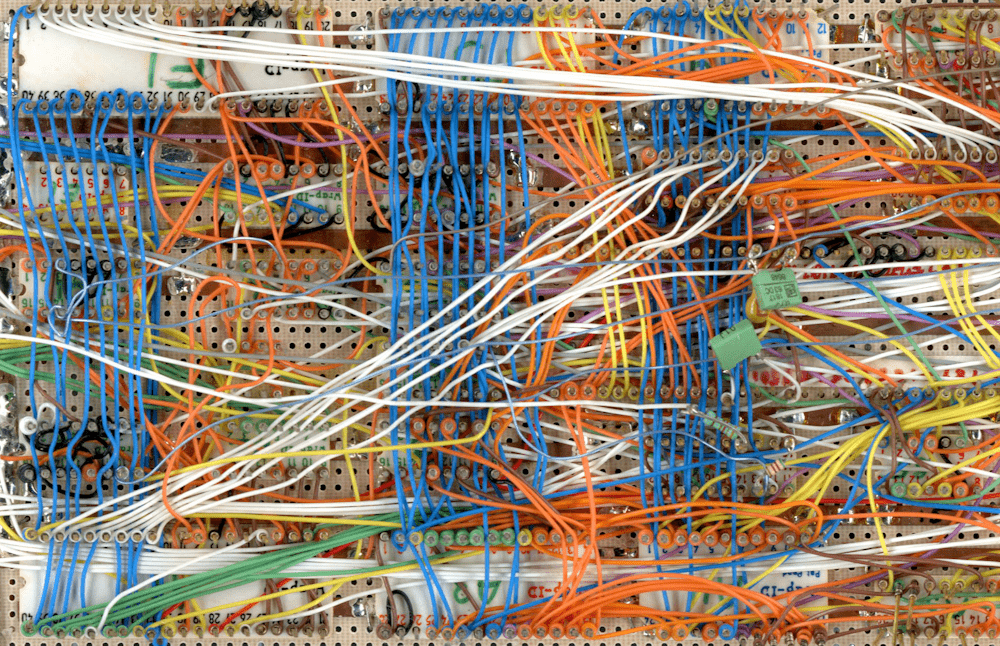

Reverse engineering is one of MTSI’s specialties. One of our early projects involved the SLC 96 developed to bring digital capability to local loop networks.

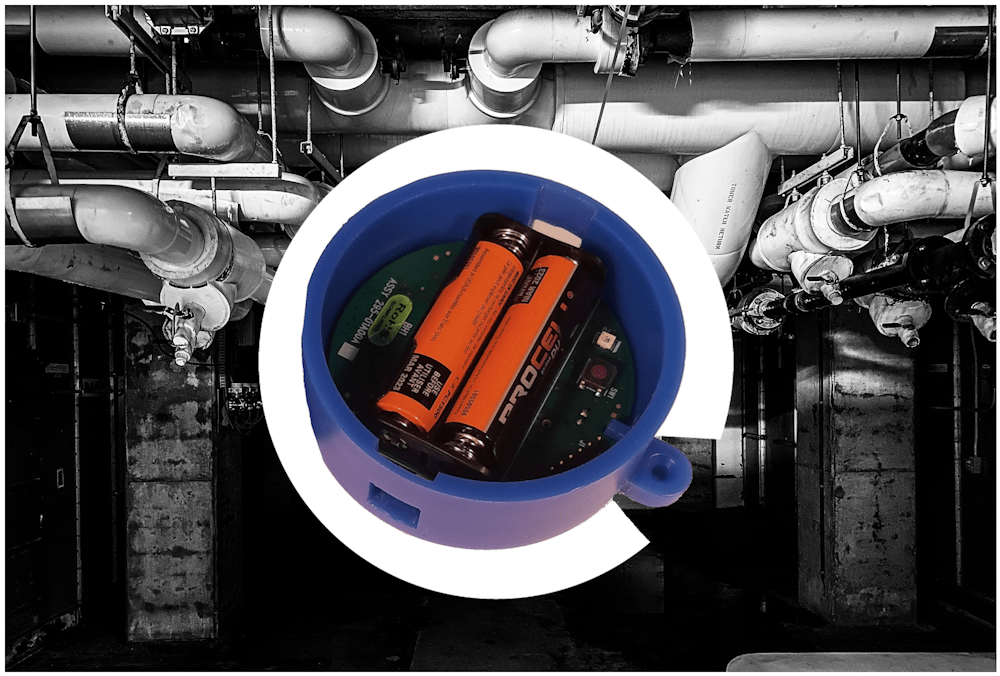

A client needed a Wi-Fi-enabled water leak detector. The design goals required a long battery life, battery voltage detection, and once-per-day heartbeat signaling to the controlling web server.

Enter the QuickCheck™ — a profitable solution from troubleshooting ECM vehicle output circuit problems. The device checks solenoids, relays, idle air and speed controls, power (chassis) and sensor ground wires.

The petroleum industry relies on downhole tools to gather critical data, optimize drilling and production operations, and ensure the overall efficiency and longevity of oil wells. MTSI developed one such tool to assist clients in making informed decisions about their production strategies.

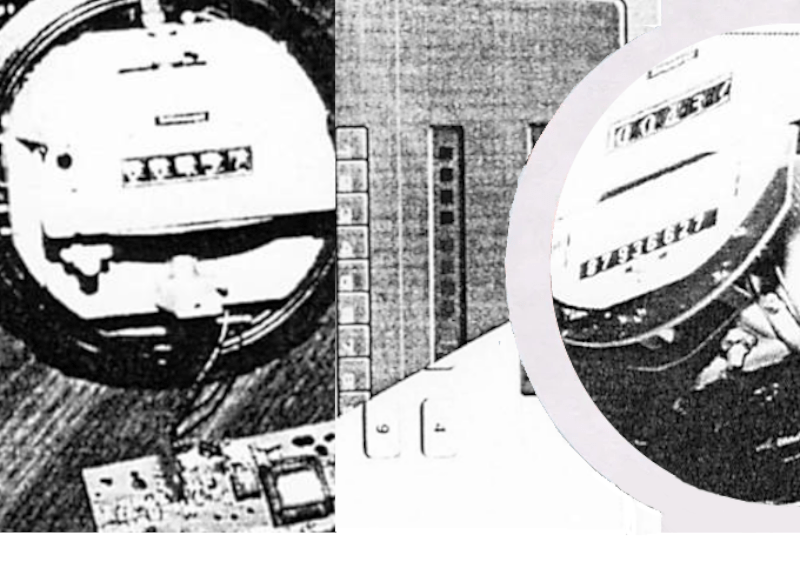

This meter module worked by measuring the rotational velocity of the electric meter’s eddy current disk using a miniature laser beam source and optical detector.

A client approached MTSI with an idea that was ahead of its time — a patented, programmable doorbell including a control for connection in series with an existing push button in a residential circuit.

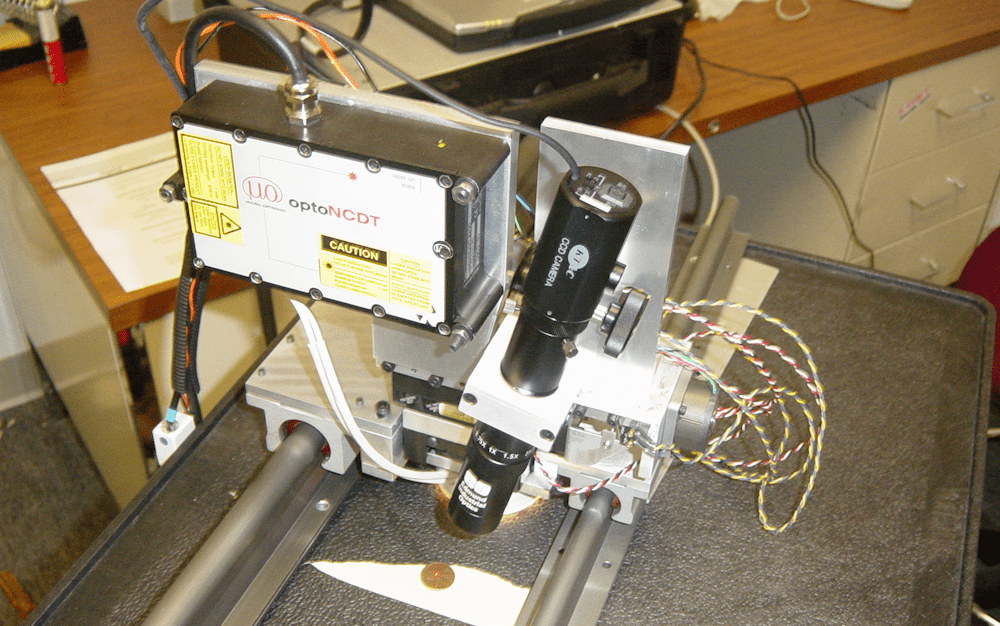

A large manufacturer of surgical gloves expanded its production. They had to meet exact standards. MTSI met the challenge.

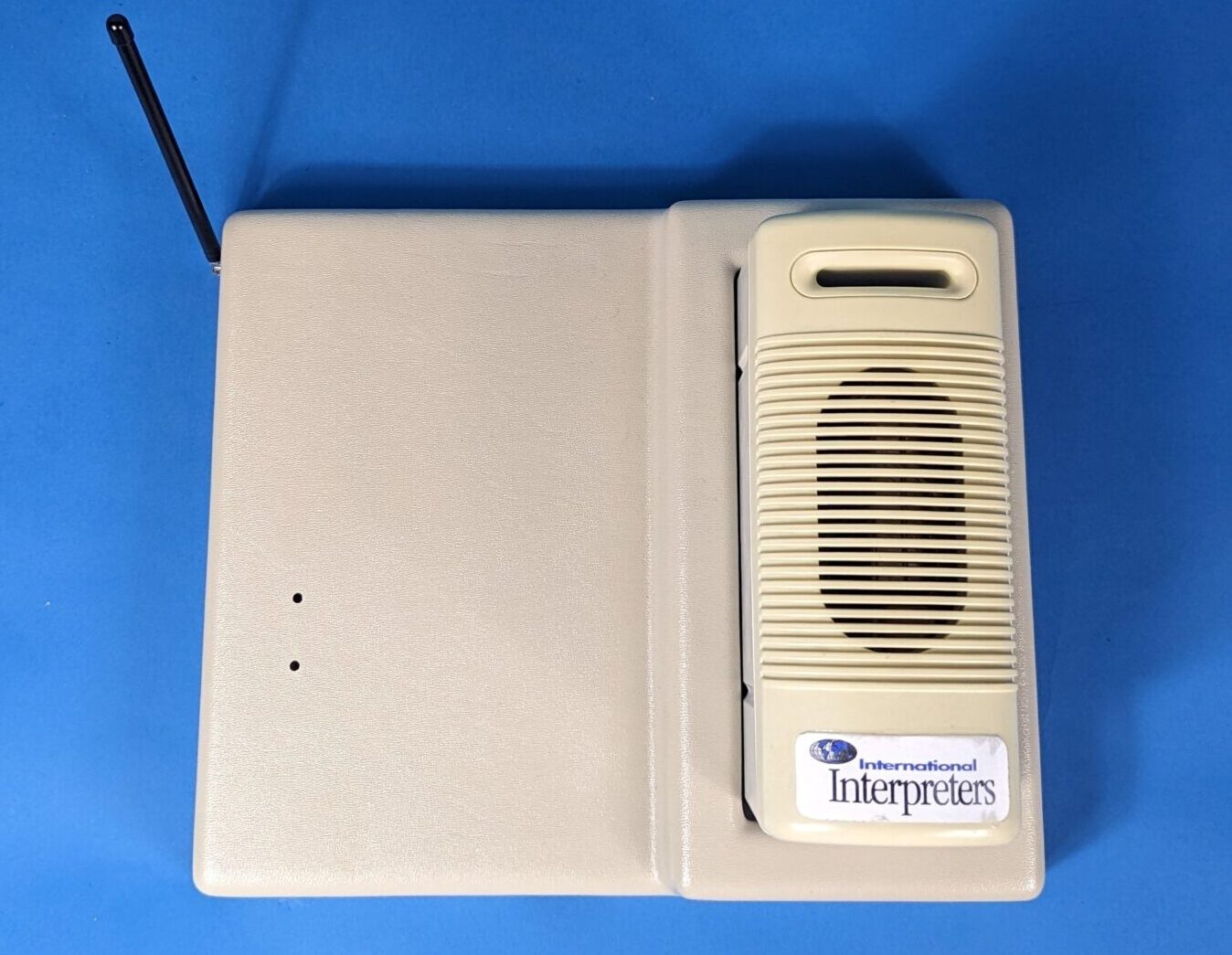

Interpretation telephone connected patients and physicians in real time.

To operate safe and reliable telecom system, the company came to MTSI to design the equipment to track down the source.

Epic Data International approached MTSI to help design a workstation solution that delivers advanced user identity authentication, and automated time and materials tracking for knowledge and manufacturing workers.

Epic Data International reached out to MTSI to develop a custom terminal for Lockheed Martin. The defense giant needed a low-cost, simple way to integrate sophisticated and automated identification, project tracking and secure-access capabilities in a highly sensitive environment.

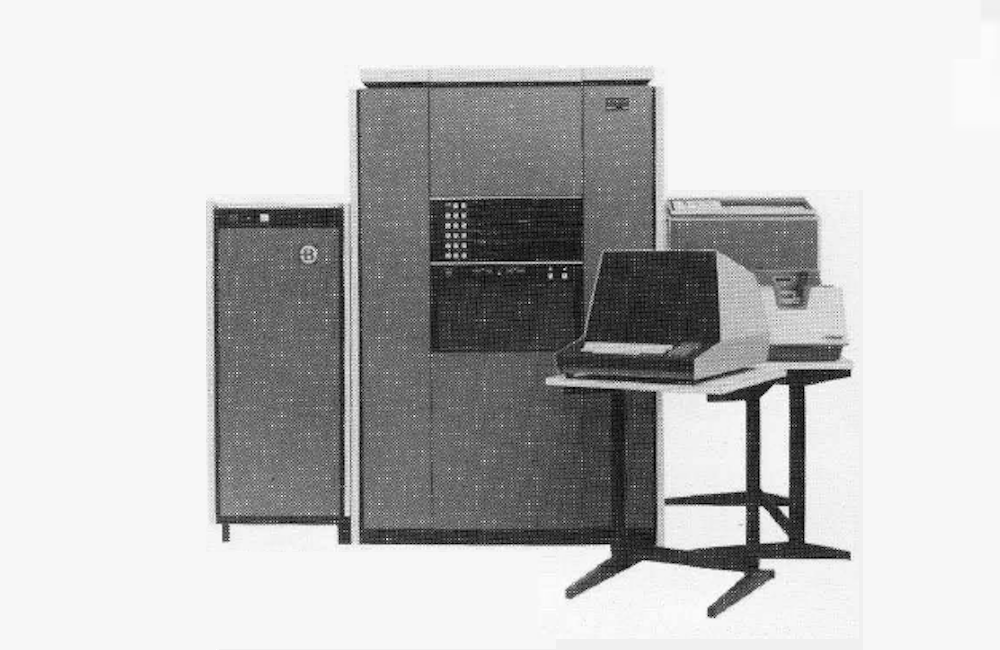

Before Dell, Compaq was the world’s top personal computer maker, and came to MTSI to help develop four new stations in their personal computer manufacturing and reliability analysis laboratories.

A consortium had defined a new Extended Industry Standard Architecture (EISA) bus computer market. These computers were to be used for high-speed file servers and work stations, and required new disk, tape, and printer controllers.

For decades, law enforcement have supervised parolees with electronic tracking devices embedded in ankle bracelets. MTSI was one of the early designers of the technology.

A client developing a new-generation automotive burglar alarm for the Ford Taurus was behind schedule. MTSI leveraged its experience in precision and swiftness to bring the project on time and to completion.

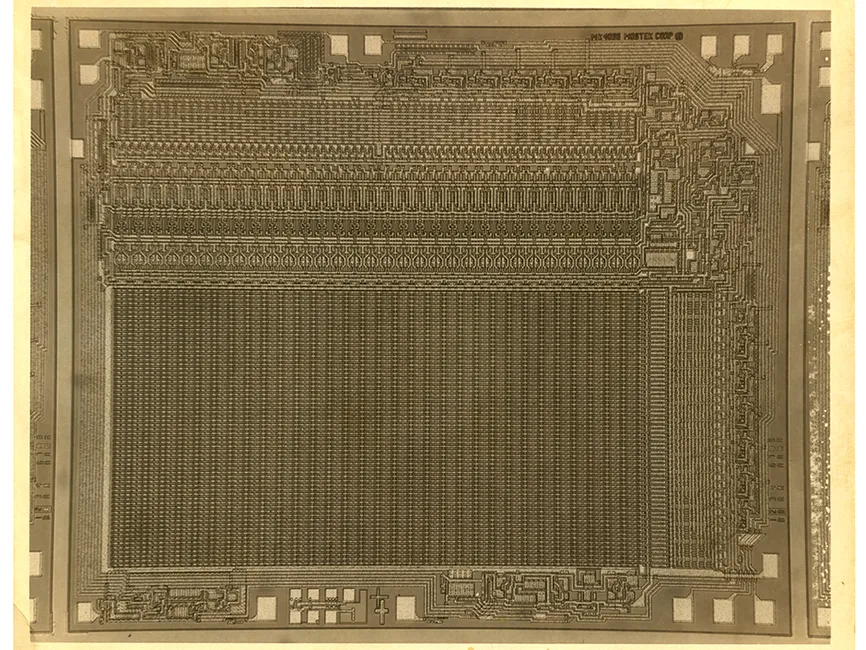

Dynamic random-access memory, or DRAM, is commonplace today in computers which use it to run their programs. Back in the 1970s, Mostek was emerging as the world’s top DRAM manufacturer and developed a circuitry trick called address multiplexing.

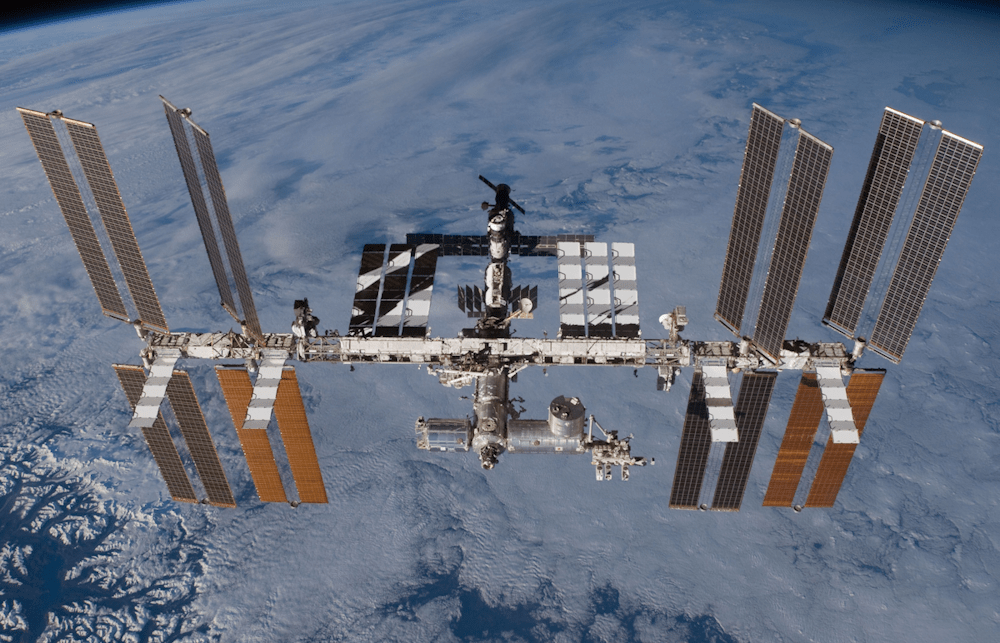

The MTSI manufacturing department built the electronic portion of the Krug Life Sciences platform for use on the International Space Station.

If you used a Z80 chip back in the 1980s, it almost certainly passed through a single room and its Farchild Sentry 610 test system. Mostek had grown into the one’s top producer of DRAM, and every Z80 microprocessor went through tests there.

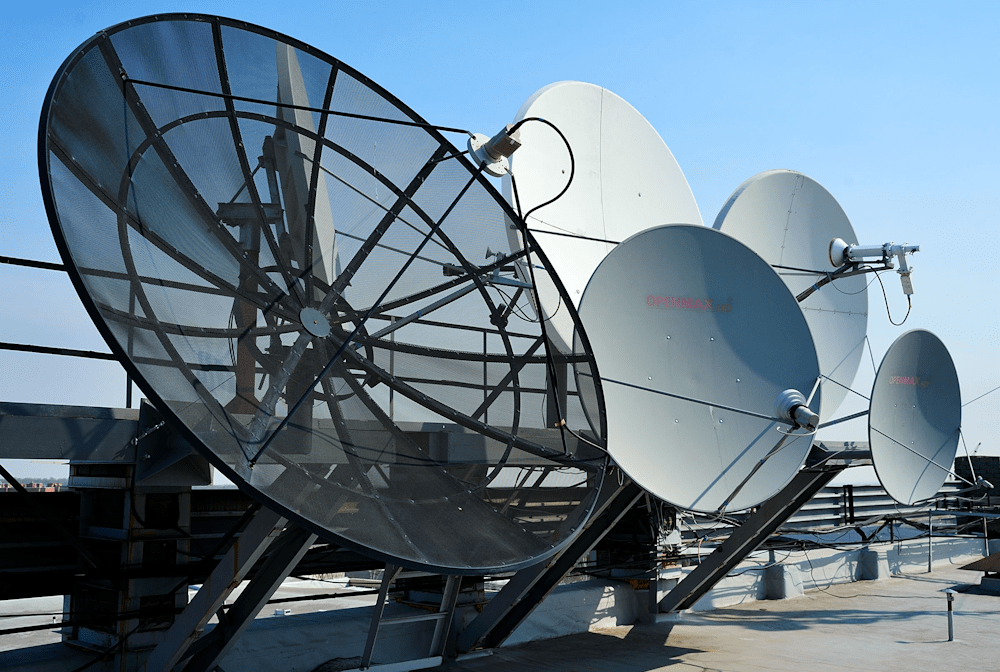

A major satellite T.V. company in the U.S. pay-per-view market had a system to provide multi-video graphics services for hotels and hospitals. MTSI engineers conducted a comprehensive study of the entire system, and followed up with the redesign that the company needed.

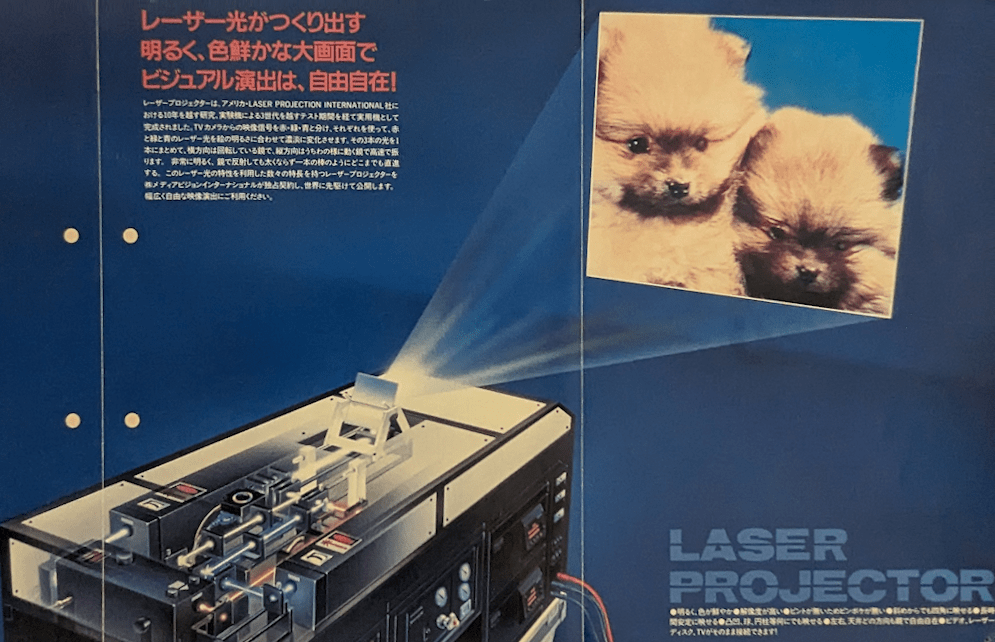

There’s nothing like blasting out an image the size of a behemoth to light up a dark room.

Every bowling lane needs to know when a player has bowled a strike or sunk the ball into the gutter. The task falls to electronic pin fall detectors. MTSI developed a system to check accuracy and repeatability.

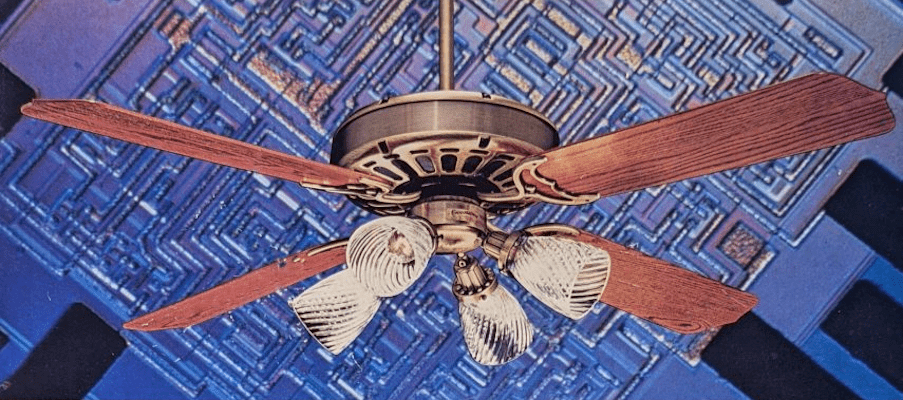

Long ago, Casablanca Fan Company — an industry leader in luxury ceiling fans — developed an innovative idea to control a ceiling fan and a lamp. With technical support from MTSI, production rapidly expanded.