MTSI Elevates Product Reliability With CompaCLEAN-III PCB Cleaning System

Engineered for high-reliability PCB manufacturing

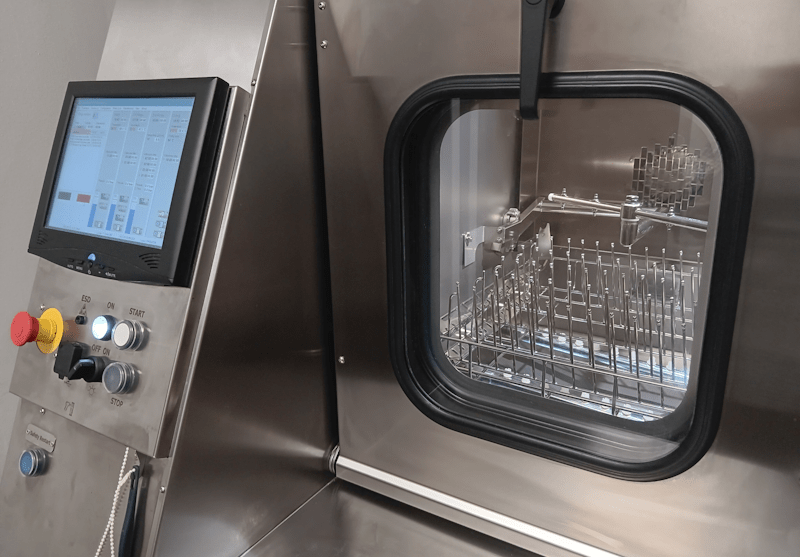

Micro Technology Services, Inc. (MTSI) has successfully installed the CompaCLEAN-III PCB cleaning system, a cutting-edge, fully automated solution that enhances that enhances speed, consistency, and reliability at our printed circuit board facility. The system is now operational, optimizing production workflows and elevating quality standards.

This advanced system combines speed, consistency, and process control to help drive defect rates toward zero while keeping production moving efficiently.

The CompaCLEAN-III integrates dishwasher-style loading with a closed-loop wash, rinse, and drying process. Each stage — wash, dual rinse, and hot-air dry — uses dedicated pumps and filtration to maintain stable operation and ensure consistent results across every board.

Residues from flux and soldering materials can cause corrosion and electrical leakage over time. Ionic contamination conducts electricity, creating the risk of latent field failures. By using deionized water, automated chemistry control, and closed-loop filtration, the CompaCLEAN-III removes these risks and ensures long-term stability of every board.

The system delivers measurable improvements to MTSI’s production workflow:

- Reduced cycle time through automated cleaning and drying functions that minimize operator intervention.

- Uniform quality from oscillating baskets and fixed spray bars that provide complete spray coverage.

- Precision chemistry control with real-time concentration monitoring and automated dosing to maintain consistent cleaning performance while reducing waste.

- Full process traceability using barcode and 2D code scanning with complete digital logging for compliance and customer reporting.

- Operational efficiency from closed-loop filtration, eliminating manual refills and unnecessary downtime.

By adopting the CompaCLEAN-III, MTSI enhances its capability to meet the demanding requirements of high-reliability industries, including aerospace, defense, medical, and telecommunications, where stringent standards necessitate repeatable, verifiable processes and flawless quality.