Offshore PCB Manufacturing Is Getting Risky—Here’s the Better Option

The global supply chain has changed. So has the smart way to build your boards.

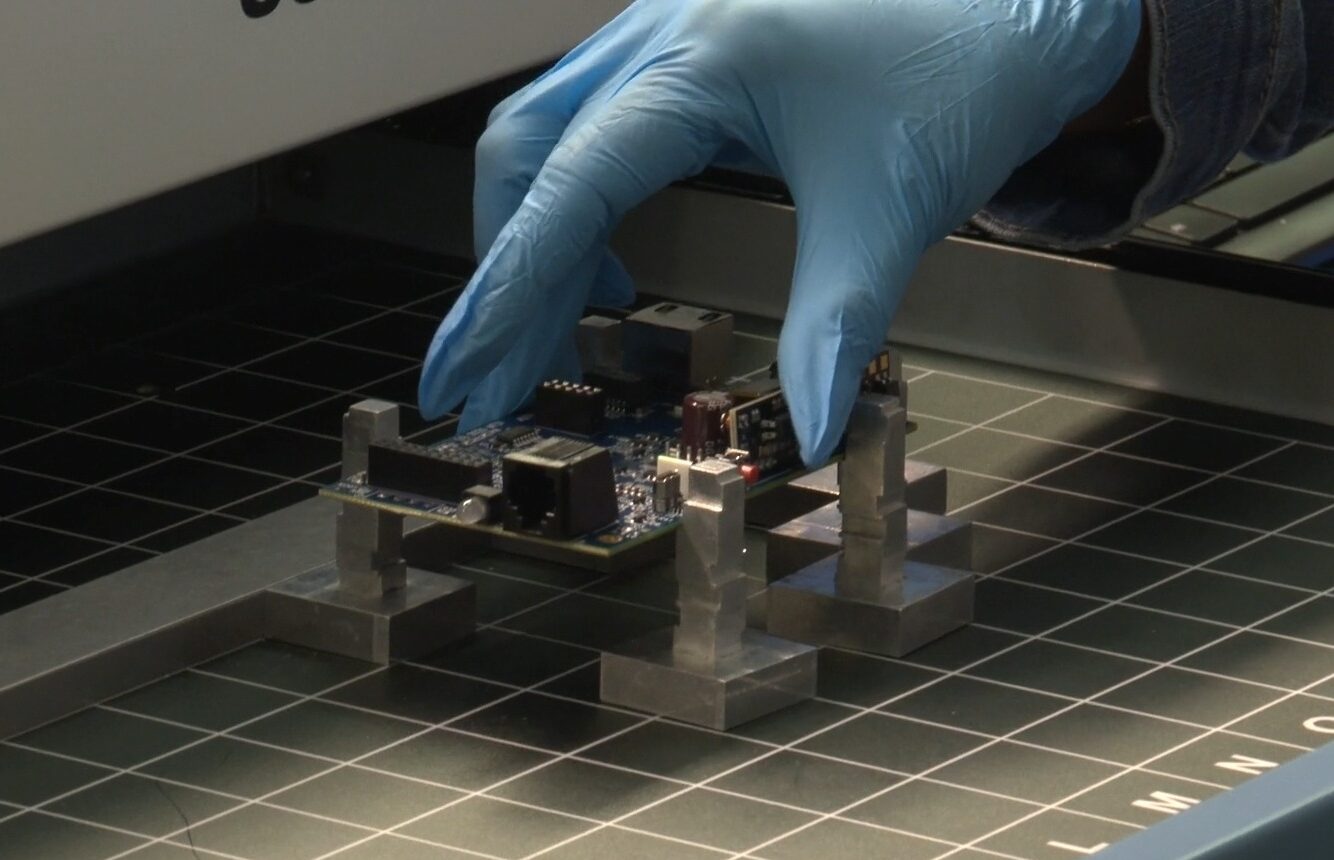

Our team at Micro Technology Services, Inc. (MTSI) recently added a new SMT machine to our production floor — effectively doubling manufacturing capacity.

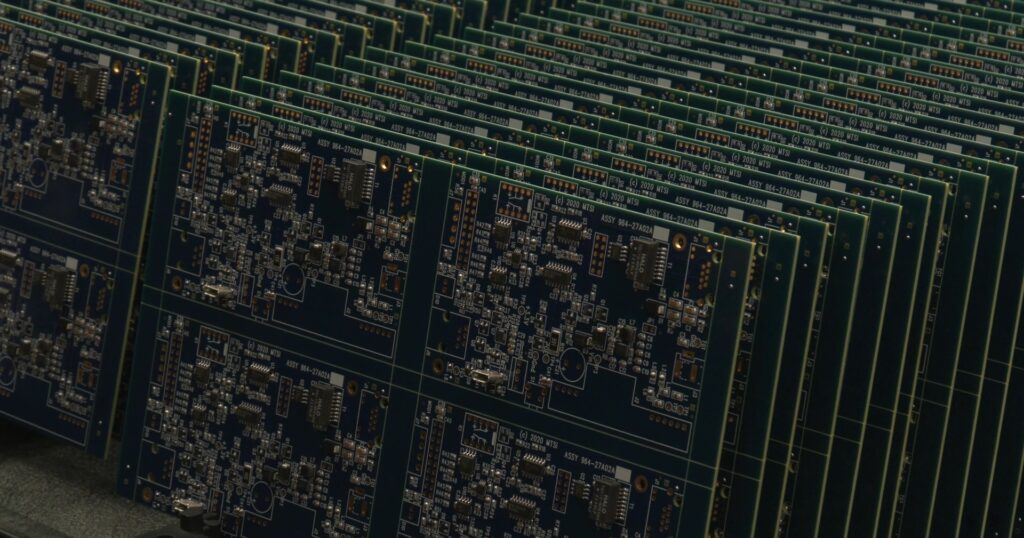

We made this investment in response to a clear trend: more companies are shifting production back to the U.S. to gain speed, control, and stability in the face of global supply chain disruptions. With geopolitical uncertainty, rising offshore costs, and growing demand for localized support, nearshoring isn’t just a tactical choice — it’s become a competitive advantage.

“Our customers are telling us the same thing across the board,” MTSI CEO Fred Beckhusen said. “They need partners who can move fast, adapt quickly, and protect their IP. That’s why we’re expanding—so we can help more teams build smarter, right here in the U.S.”

American businesses partnering with domestic PCB manufacturers isn’t just an alternative, it’s a smarter, more resilient way to build electronics. At MTSI, we’ve helped customers across industries—from aerospace to defense to industrial automation—stay agile by providing responsive, high-quality PCB design and manufacturing right here at home.

As lead times tighten and global risks grow, the ability to move fast, protect IP, and adapt quickly isn’t optional.

When Speed Matters, Proximity Wins

In today’s development environment, speed isn’t a luxury—it’s a necessity. Delays from overseas vendors, inconsistent communication, and unexpected shipping issues can easily derail your product timeline.

By partnering with MTSI, you eliminate many of those barriers. We also go a step further.

We specialize in helping teams under pressure—clients who are overloaded, behind schedule, or stuck mid-cycle. Our engineers are used to jumping into complex builds fast, helping finalize designs, manage production, and get things back on track under tight deadlines. When you’re in a crunch, we become an extension of your team.

Your Designs. Your IP. No Compromises.

Your electronic designs are more than just blueprints—they’re valuable intellectual property. Unfortunately, outsourcing PCB manufacturing overseas often means putting that IP at risk. Designs can be copied, modified, or exposed to third parties—sometimes without you even knowing it.

That’s not how we work at MTSI.

When you work with us, you own 100 percent of your intellectual property. Schematics, layouts, and firmware stay protected, period. Our clients know that when they hand over sensitive files, they’re in trusted hands—and that’s one of the reasons they stay with us year after year. For industries like defense, where compliance and confidentiality are non-negotiable, this level of security is absolutely critical.

Total Cost Isn’t Just a Number on a Quote

It’s easy to get lured by low unit prices from overseas vendors. But today’s offshore manufacturing environment is not what it was five years ago. Rising wages in Southeast Asia, increased tariffs on imported electronics, and record-high global freight costs have all pushed prices upward.

Labor costs in China have increased by more than six percent annually since 2020

Tariffs on Chinese-made electronics components remain between 15 and 25 percent

Ocean freight rates are up over 30 percent year-over-year, with recurring port delays and container shortages

When you add in rework, communication overhead, and the cost of delays, that “cheap” board often turns out to be anything but. In contrast, domestic PCB production often delivers a better total cost of ownership, especially when you value agility, quality, and time to market.

Readiness and Resilience

The decision to build your boards with us isn’t about looking backward—it’s about preparing for what’s ahead. The electronics industry is moving faster than ever. Customer demands are evolving, timelines are shrinking, and the risks of relying on long, fragile supply chains are only growing worse.

Reshoring your PCB manufacturing is a strategic move that gives you more control over quality, costs, and continuity. It means working with partners who understand your needs, who can collaborate in real time, and who are invested in your long-term success—not just the next order.

We’ve built our reputation by being that kind of partner. We serve clients in aerospace, defense, industrial automation, and beyond—offering full-stack design support, in-house manufacturing, and the kind of hands-on responsiveness that gets projects done when others can’t.

If you’re tired of waiting, reworking, or worrying about the next international delay—let’s talk. We can help you streamline production, protect your IP, and deliver the quality your customers demand—right here in the United States.

Contact us today to start the conversation.

Robert Beckhusen

Robert Beckhusen is a case studies and content marketing editor for Micro Technology Services.