The 3D Scanner That Saved a Telecom System

For want of a flat washer, a telephone exchange died

A manufacturer of rack-mount telephone switching equipment had a design flaw in their gear that caused a fire in a telecommunications facility. To operate safe and reliable telecom system, the company came to MTSI to design the equipment to solve the problem.

It was easy to see what went wrong. Located in each seven-inch rack there were two card cage assemblies with respective backplane assemblies. The manufacturer had attached the backplane connectors with a #4-40 screw and a single tooth lock washer without a flat washer underneath. Compounding this mistake, the power plane was located just below the external ground plane and did not have a keep-out zone.

When the screws were tightened into the soft PCB material, a short between the two planes occurred.

The challenge was fixing the problem while the telecom equipment remained powered up and functional. There were eight zones on each backplane assembly, and each zone had 16 screw points that needed to be measured and documented by an inspector, one after another.

Moreover, the system was covered in copper cables, blocking the measurement points, and they could not be removed during the job — only nudged slightly out of the way. That required creative engineering with a custom-made 3D scanner.

The scanner saved the physical network and improved network reliability.

3D Scanner to the rescue

Solution

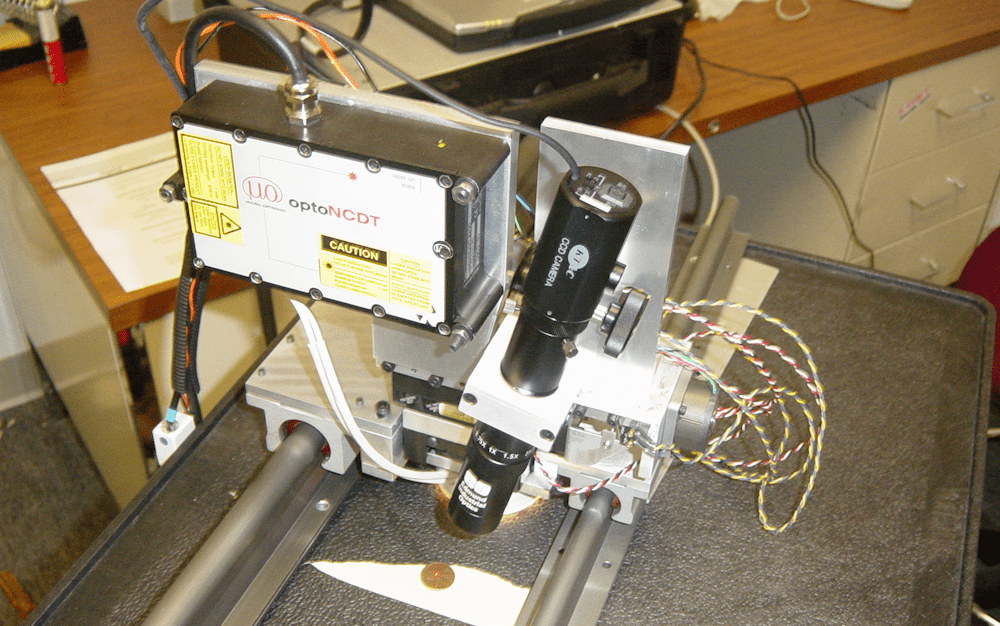

MTSI was contracted to build a 3D scanner that was used to scan the depth of the dent in hundreds of small dents in the backplane. An OptoNCDT laser rangefinder and a digital microscope were attached to a custom frame with stepper motors. The inspector could then attach the device to the backplane to get a solid and stable reference point without shutting off the entire telecom system

A LabView program then scanned the area of the dent, drew a 3D image of the dent, and measured the depth of the deepest dent after calculating the average surface as a reference point. The client located the root source of the electrical short. The scanner saved the physical network and improved network reliability.