// Contract Engineering Services

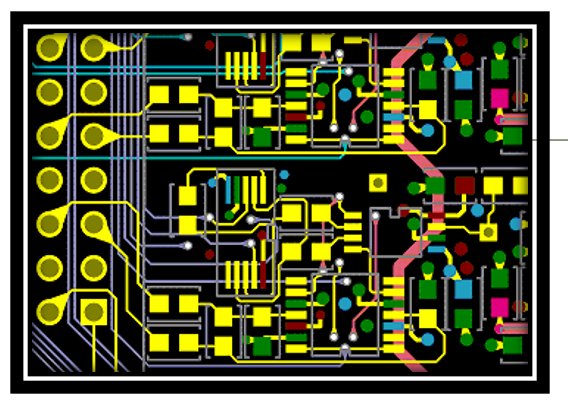

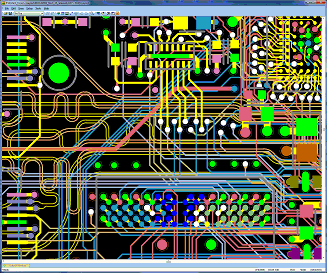

Custom PCB Design & Layout

We are fully qualified to work on the toughest and most challenging custom PCB design and layout jobs – and the easy ones, too. Custom PCB design is a complex and challenging task, but it is essential for the development of high-quality electronic devices.

MTSI meets the challenge with exceptional quality.

If your schematics include trade secrets or proprietary information, we will sign your non-disclosure agreements – or provide you with one of ours – to protect your intellectual property.

- PCB Layout

- Mentor PADS Accel Layout

- Schematic Entry

- Signal Integrity/Power Integrity