The Casablanca Fan

Improving reliability, increasing delivery

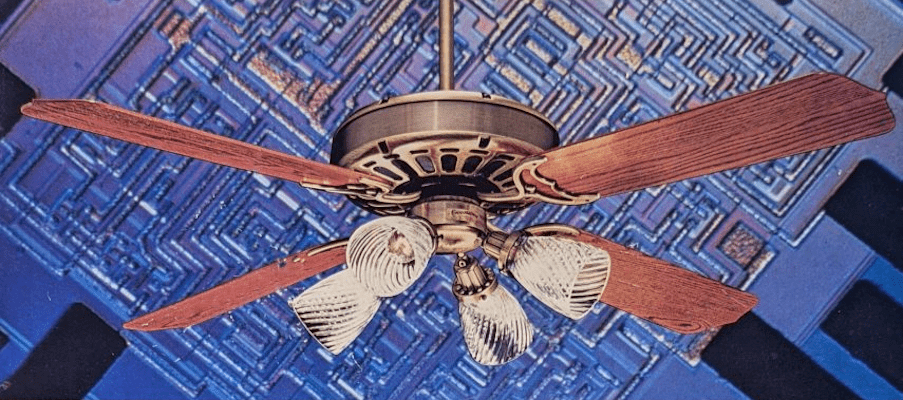

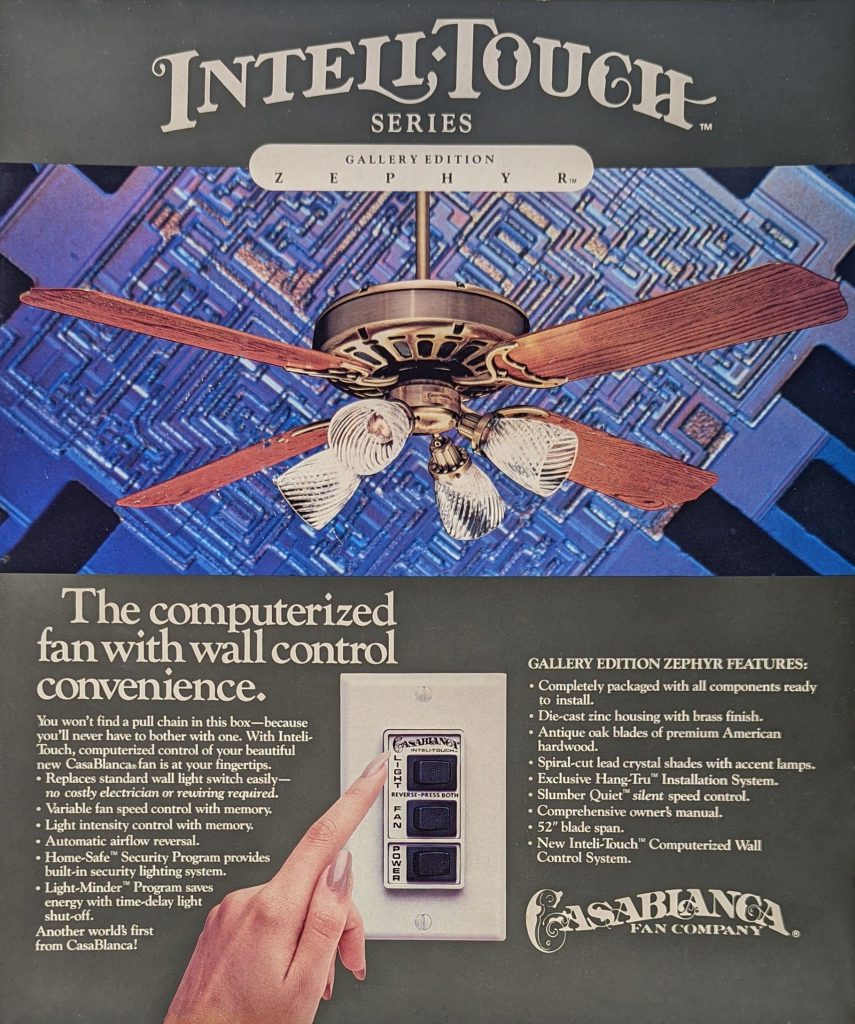

Long ago, Casablanca Fan Company — an industry leader in luxury ceiling fans — developed an innovative idea to control a ceiling fan and a lamp.

The company’s engineers interrupted the power line in the fan for a brief moment as it crossed through zero volts — a neutral point in the circuit. An alternating current has an up-and-down cycle, which gave Casablanca two controls.

A TMS-1000 4-bit microprocessor was used to detect the power cycles and to control the Casablanca fan blades and lamps.

Casablanca also needed testing equipment to ensure reliability during manufacturing. At MTSI, we’re invested in bringing solutions to our clients in need of rapid, high-quality contract engineering services.

Increased production with a smooth switch

Solution

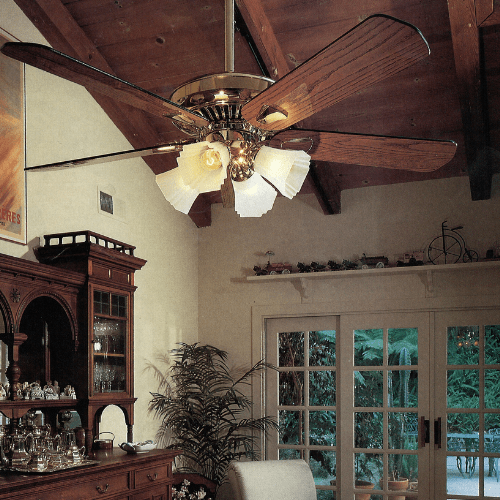

Our team helped Casablanca develop the high-speed, automatic test equipment for their fan control module on the production line — enabling their manufacturing processes to increase with greater efficiency, reliability and scale. This allowed the team to expand production, minimize downtime, and continue to deliver millions of fans for years into the future.

The core of the test system was a microprocessor-controlled bed-of-nails fixture and a custom hardware platform. A second generation of 8-bit designs controlled two test heads.

With technical support from MTSI, the production rate for the ceiling fan accelerated and reached more than 1,000 units per month within four months. Casablanca has sold millions of fans and has used multiple generations of more advanced circuitry as it became available: 4-bit, and then 8-bit chips, with radio and power line signals.

In each successive generation, the operator inserts the fan module into the test head and lowers the lid. A magnetic switch detects the closure of the test head, energizing a latch and activating the test start sequence. The test is completely automatic, with failure codes and reports logged to a printer. The computer control is a custom microprocessor-based system developed by MTSI for use in dedicated testers.

The test equipment requirements were complicated by the 110-volt operation of the Casablanca fan module. All tests had to be run at line voltage, requiring hazardous line voltages to be isolated from the operator. The resulting test takes only a few seconds to completely check the board and 4-bit computer.

Impact

It’s easy to see why this system is still in operation after more than 30 years and millions of units sold. We are proud to have been a small part of Casablanca’s huge success.

Robert Beckhusen

Robert Beckhusen is a case studies and content marketing editor for Micro Technology Services.