A regional government complex with diverse facilities required rapid communication during emergencies. We provided a reliable, efficient alarm system to address threats and maintain security.

Lynx Systems demonstrates commitment to data security, compliance, and customer trust in every operation

Lynx Systems launches Axis ACAP for seamless, secure device integration across networks.

Inside a 16,000-square-foot facility in Richardson work 40 “geniuses” who can design anything from next-generation telecommunications switching components to talk doorbells. The company’s president thinks its time his employees get some recognition.

Micro Technology Services, Inc. (MTSI) proudly announces that we have completed our ISO 9001:2015 certification as of Oct. 21, 2014, affirming the company’s ongoing dedication quality and customer satisfaction.

In the realm of government operations, ensuring the safety of personnel and the public is paramount. Particularly in emergencies, the ability to communicate quickly and effectively is not just beneficial but also necessary.

Lynx Systems proudly announces Fernando Esteban, a renowned professional with a remarkable track record spanning 29 years in the Network Video, Security, and Technology Industries, as the new National Sales Director.

This state-of-the-art facility offers visitors a firsthand look at the company’s advanced wireless duress and mass notification solutions, highlighting Lynx Systems’ ongoing commitment to providing innovative safety technologies for organizations across industries.

Lynx Systems, a leader in duress and mass notification solutions, proudly announces a strategic partnership with IPVideo Corp, a Motorola Company.

As Inovonics evolves its products to cloud-based systems, some entities may face restrictions against using such solutions. As a dedicated partner of Inovonics, Lynx Systems is prepared to bridge this gap with our state-of-the-art security solutions, including robust panic buttons and duress management systems.

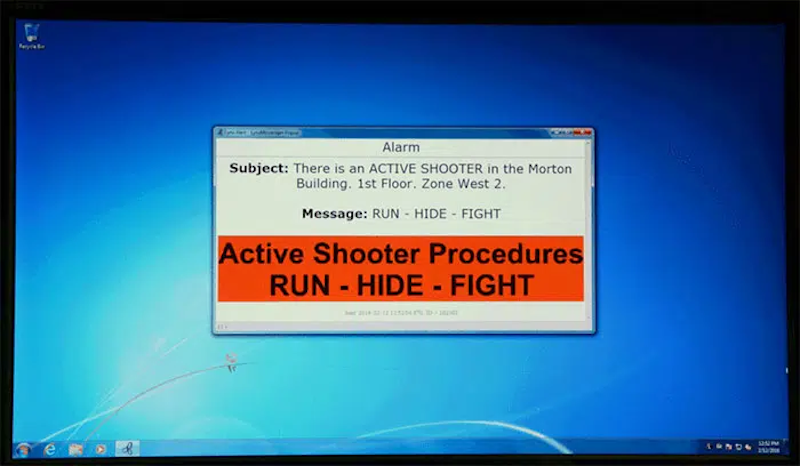

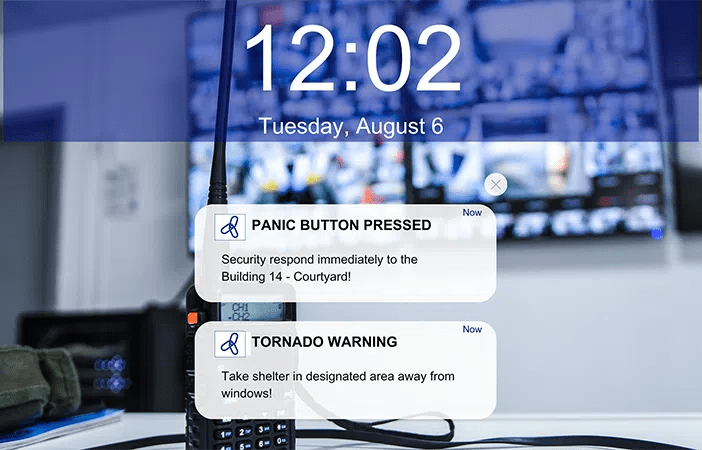

In our ongoing commitment to enhancing security management, Lynx Systems focuses heavily on the efficiency and effectiveness of real-time alerts within our security solutions. Our sophisticated alert system is engineered to deliver immediate notifications, enabling our clients to manage and respond to emergencies swiftly and decisively.

Lynx Systems, a leader in security and mass notification systems, today reaffirmed its commitment to enhancing security at government facilities with its proven suite of security solutions. Strategic partnerships support this affirmation, along with significant contract wins with various government agencies.

Lynx Systems, a trailblazer in providing innovative network-based Duress and Mass Notification, proudly announces its recent certification from Genetec, a globally recognized leader in security and intelligence solutions.

Late one night in 1977, I discovered one of the world’s first computer viruses.

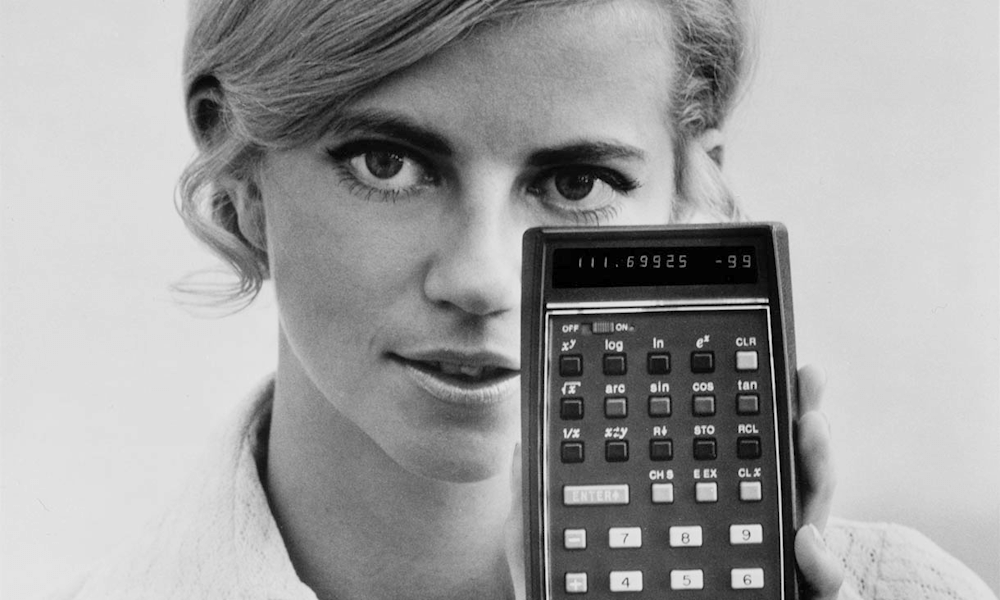

The HP-35 calculator was the first handheld, battery-powered scientific calculator. I was awestruck and had no idea that I would soon work on them at an intimate level at the very company that designed and made the HP-35 ICs.

Lynx Systems, a leading innovator in network-based Duress and Mass Notification, is proud to announce the strategic partnership with INFOPIPE to meet the growing demand in the dynamic Florida market.

Lynx Systems, a leading builder of duress and mass notification networks, announced LynxNet Messenger2 with remote control. The device works with a customer-supplied monitor or public viewing monitor to visually display a message of the customer’s choosing.

For many years, MTSI has been proud to design and manufacture printed circuit boards (PCBs) which power the equipment used in wafer processing.

The county government of this well-populated region of Washington chooses Tyco Security Products’ C•CURE 9000 Security and Event Management system to upgrade its facility access control and deploy its new Lynx Network Duress and Emergency Notification System.

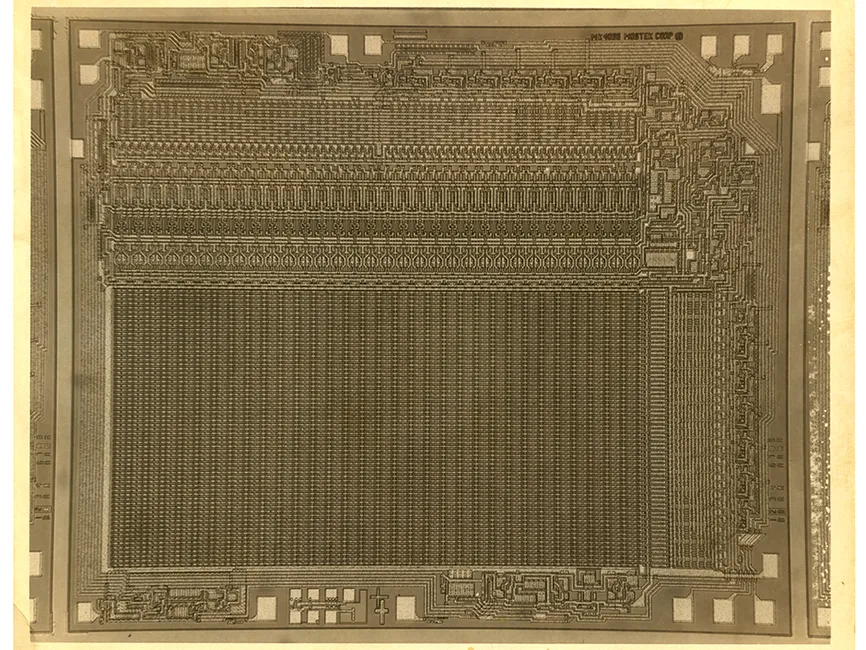

Dynamic random-access memory, or DRAM, is commonplace today in computers which use it to run their programs. Back in the 1970s, Mostek was emerging as the world’s top DRAM manufacturer and developed a circuitry trick called address multiplexing.

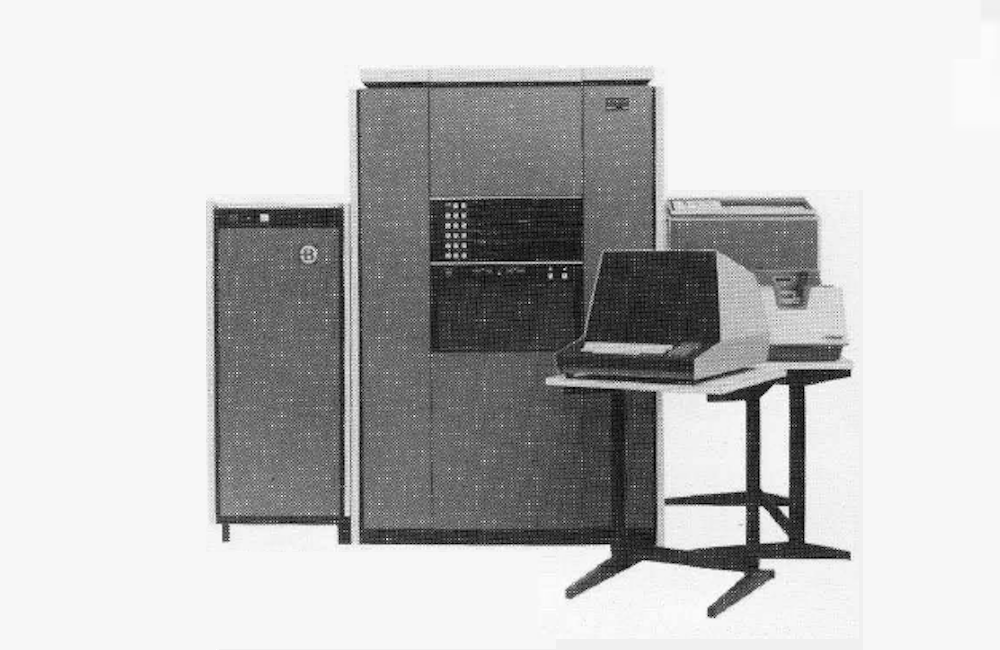

If you used a Z80 chip back in the 1980s, it almost certainly passed through a single room and its Farchild Sentry 610 test system. Mostek had grown into the one’s top producer of DRAM, and every Z80 microprocessor went through tests there.

Lynx Systems has been featured Security Journal Americas with Lynx Systems Sales Director Fernando Esteban. Esteban discusses how alarm and intruder detection systems have evolved to include panic buttons.